[Hebei, China — October 2025] The warehouse software market is entering a pivotal growth phase. According to a report, the Warehouse Management System (WMS) market is projected to reach USD 9.2 billion by 2034, nearly doubling from 2024. This rising demand underscores the strategic importance of software in modern logistics operations.

As warehouse automation (shuttles, stacker cranes, mobile systems, rack-supported designs, etc.) becomes central to logistics infrastructure, software layers like WMS and WCS are no longer optional—they’re essential. HEGERLS brings its own software solutions into the conversation: CC-WMS and YUNTU-WCS, complementing its hardware portfolio to deliver fully integrated, intelligent warehouses.

Key Market Insights

Deployment Models

On-premises WMS still accounts for about 60% of installations due to customization and control. However, cloud WMS (~40%) is growing rapidly, offering scalability and reduced IT overhead.

Core Functional Modules

Inventory Management (~30% share)

Order Fulfillment (~25% share)

Labor & Resource Management

Transportation & Yard Management

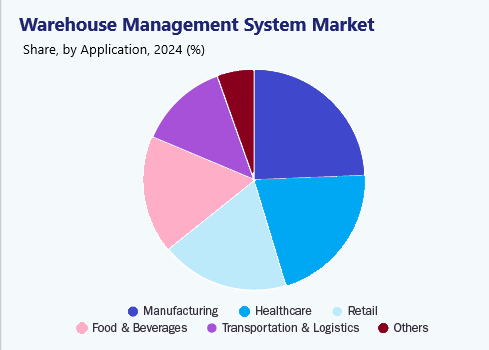

Industry Adoption

Manufacturing leads (~25%), followed by healthcare, retail, F&B, logistics/transportation, and others.

Regional Landscape

North America remains dominant, while Asia-Pacific is the fastest-growing region, driven by e-commerce growth, urban warehousing, and manufacturing investment.

Integration with Hardware

As warehouses deploy AS/RS systems, shuttles, AMRs, drive-in racks, and rack-supported structures, robust software control is needed to coordinate movements, maintain throughput, enforce constraints, and maximize efficiency.

Rising Investment in WCS

Warehouse Control Systems (WCS) sit between WMS and the physical hardware, translating high-level tasks into real-time commands. Their role is critical in high-throughput, high-density automation systems.

Why WMS Growth Matters for Automation

The WMS has evolved from a record-keeping tool into a real-time orchestration engine. It now governs everything from order prioritization to shuttle dispatching, stacker crane routing, and predictive maintenance of mobile robots.

As warehouses adopt AS/RS systems, autonomous mobile robots (AMRs), IoT sensors, and AI-powered analytics, the WMS acts as the “digital brain,” ensuring seamless integration across technologies.

HEGERLS Warehouse Management and Control Software:

CC-WMS & YUNTU-WCS

To respond to the software-centered future, HEGERLS has developed:

CC-WMS (HEGERLS Warehouse Management System)

Provides end-to-end warehouse management functions: inventory tracking, order fulfillment orchestration, slotting optimization, labor/resource planning, and analytics dashboards.

Supports hybrid deployment (cloud, on-premises) to suit client technical and investment preferences.

Integrates seamlessly with HEGERLS automation hardware (shuttles, stacker cranes, drive-in racks, mobile racking).

Enables scalable expansion and modular upgrades as warehouse needs evolve.

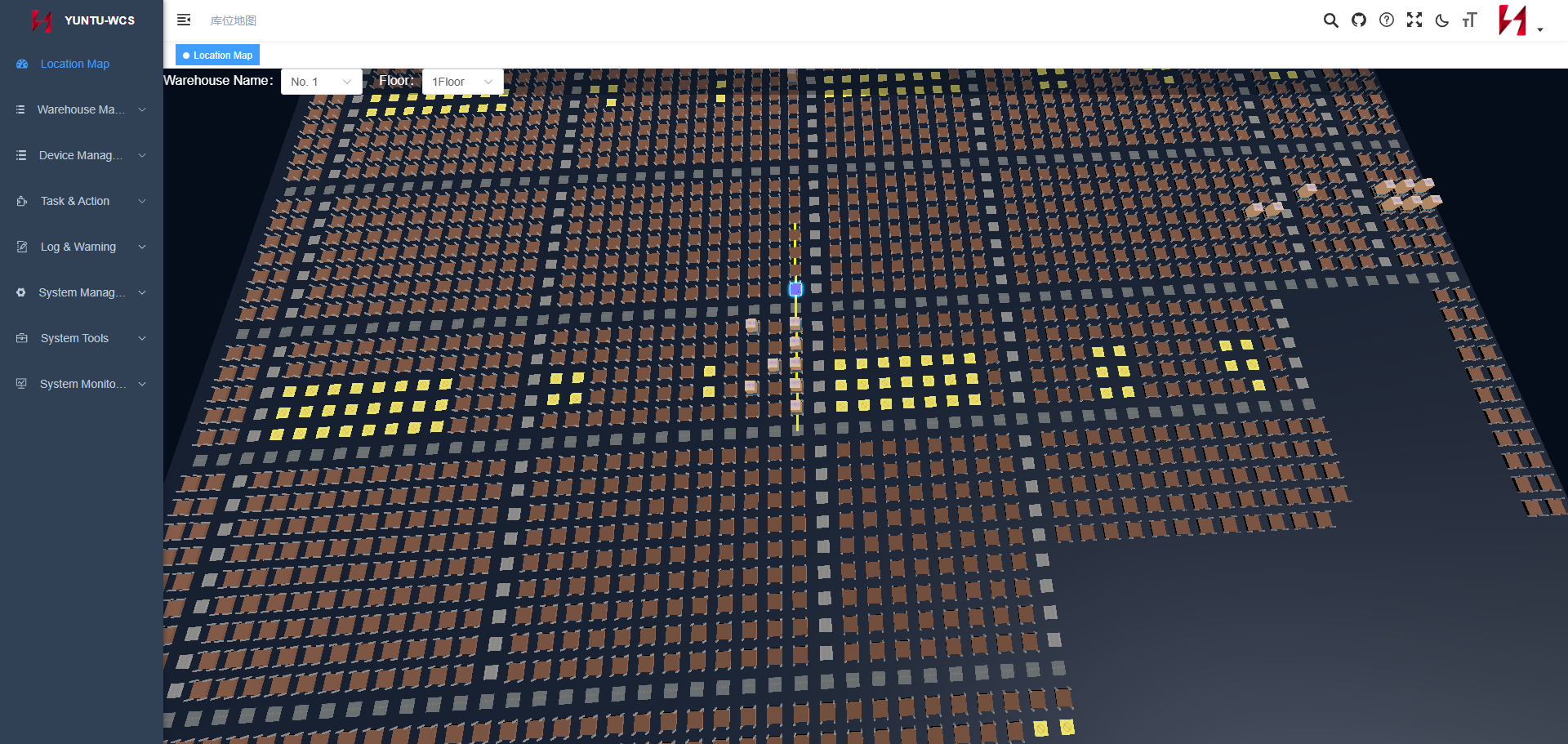

YUNTU-WCS (HEGERLS Warehouse Control System)

Operates at the control layer, issuing real-time commands to shuttles, stackers, and conveyor/AGV systems.

Manages conflict resolution, traffic coordination, safety logic, and priority scheduling in dense automation environments.

Provides real-time monitoring, fault handling, and feedback loops to the WMS layer.

Ensures high throughput and high reliability, especially when coordinating multiple subsystems (multi-directional shuttles, mobile racks, etc.).

With CC-WMS + YUNTU-WCS, HEGERLS can offer clients not just storage hardware, but complete hardware + software stacks — a major differentiator in a market where software growth is rapidly overtaking hardware as a strategic driver.

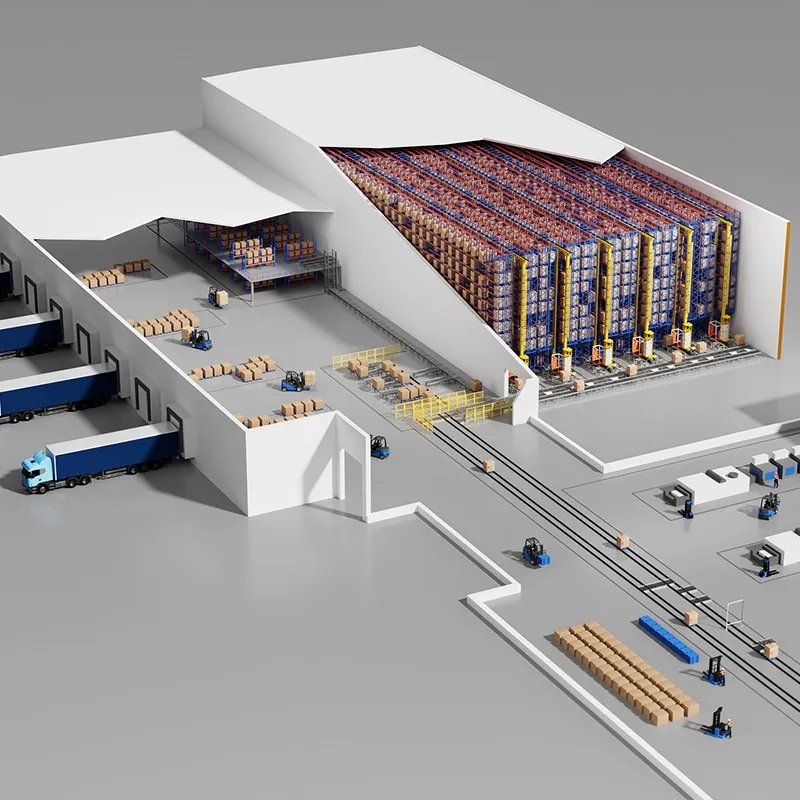

Integrated Automation Solutions with HEGERLS

In the combined hardware + software paradigm, HEGERLS delivers solutions such as:

Two-Way, Four-Way, Six-Way Shuttles

Coordinated via YUNTU-WCS for motion sequencing, conflict avoidance, and throughput smoothing; directed by CC-WMS for high-level fulfillment logic.

Two-Way

Four-Way

Six-Way Shuttles

WCS schedules crane tasks, avoids collisions, balances load; WMS handles inventory logic and task allocation.

Drive-In Racking & Rack-Supported Warehouses

High-density layout enabled; WCS helps shuttles / stackers navigate within tight spaces; WMS allocates optimal slots.

Drive-In Racking

Rack-Supported Warehouses

WCS orchestrates rack movements to open pathways without human intervention; WMS ensures correct slot assignment and order picking logic.Together, these integrated systems help clients achieve higher density, higher reliability, lower operational cost, and faster ROI.

Strategic Takeaways

Software-led differentiation

As the WMS market grows, HEGERLS’s ownership of CC-WMS and YUNTU-WCS positions it as a full-stack provider, reducing integration risk for clients and increasing value capture.

Modular deployment

Clients can start with CC-WMS + basic staging automation, then grow into full WCS + AS/RS + shuttle systems.

Scalable architecture

A software backbone allows addition of future capabilities — AI forecasting, digital twin simulation, IoT telemetry, AMR coordination — without overhauling the system.

Competitive advantage in markets

In Asia-Pacific, Eastern Europe, Middle East, and emerging logistics hubs, clients prefer turn-key providers. HEGERLS can win by bundling hardware + CC-WMS + YUNTU-WCS.

Reduced total cost of ownership (TCO)

Integrated control reduces downtime, simplifies maintenance, and ensures throughput consistency, which shortens ROI.

Outlook

With the WMS market set to double or triple by 2034, the next decade will be defined by integration, intelligence, and efficiency. HEGERLS is positioning itself at this intersection by delivering hardware-software ecosystems that help clients unlock:

Higher storage density with multi-directional shuttles

Smarter operations through WMS-driven optimization

Faster ROI despite rising labor and energy costs

Future-proof scalability via modular and cloud-ready solutions

HEGERLS is ready to partner with global clients in designing intelligent, WMS-driven warehouse solutions.

Contact us today to explore how two-way, four-way, six-way shuttles, stacker cranes, rack-supported warehouses, and mobile racking — all integrated with HEGERLS's CC-WMS and YUNTU-WCS — can transform your warehouse operations.

Contact Info

Website: https://www.hegerlsstorage.com/

Email: hegerls1@hegerlsstorage.com

Phone: +86-311-87240955