Four-way Shuttle System

- HEGERLS

- Xinhe Industrial Park, Hebei, China

Product Introduction

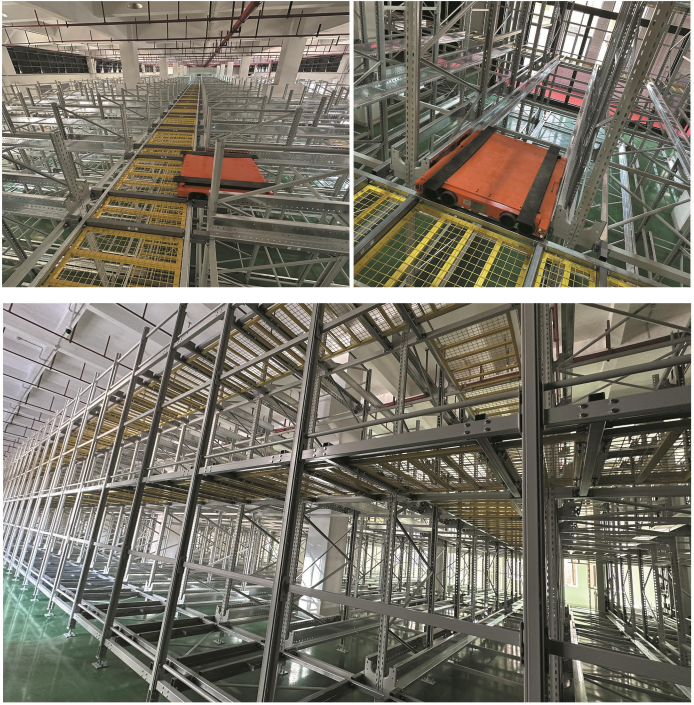

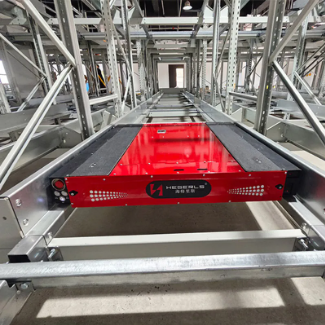

The HEGERLS Four-Way Shuttle System integrates shuttles, vertical lifts, racking, conveyors, WCS/WMS software, and other supporting systems, including remote controllers, charging stations, emergency rescue solutions, fire-safety charging points, wireless networks, and QR code tracking. This all-in-one intelligent warehousing solution ensures seamless coordination, high efficiency, and safety across various logistics scenarios.

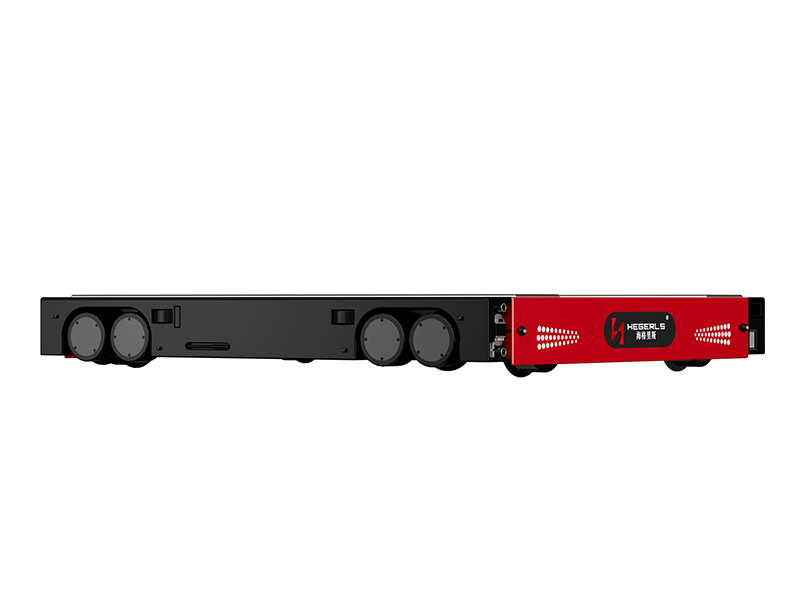

The four-way shuttle vehicle is the core equipment of the intelligent warehousing system. It has the ability to travel in four directions (front, rear, left, and right) and can freely switch between aisles on the shelf tracks. Equipped with an advanced intelligent scheduling system, it realizes fully automatic inbound and outbound operations, with a maximum load of 2 tons and a maximum running speed of 3 meters per second. Supporting multi-vehicle collaboration, it significantly improves warehouse space utilization and cargo handling efficiency, making it an ideal choice for modern logistics warehousing.

parameters

125mm

Body thickness

1000-2000kg

Rated load

3m/s

Driving speed

2s

Reversing time

Technological Innovation

All-mechanical structure

Full gearbox mechanical transmission, long service life and maintenance-free

Body thickness is only 125mm, with a load capacity of 1.5 tons

Precise positioning

Positioning accuracy of ±1mm, supporting mixed placement of pallets with different sizes within the sub-lane

Barcode + magnetic induction ± odometer positioning

Extreme speed

No-load speed: 3m/s, full-load speed: 2m/s

Lifting time: 1.5s

Network stability

High-performance WiFi enables fast roaming handover.

Scene Adaptation

Covers temperature environments from -25°C to 45°C

Adapts to various sizes of pallets and supports scene customization

Core Brain

Fully self-developed embedded controller, integrating multi-core industrial-grade processor, supporting deep learning

Higher computing power and faster response speed

Energy Reliability

Dual BMS intelligent charging protection for energy safety

Ultra-large battery capacity with 10-hour ultra-long battery usetime

Safety Protection

Laser obstacle avoidance sensors for comprehensive autonomous obstacle avoidance

Automatic pallet offset detection for more precise handling

Product Value

Flexibility and Agility

The four-way shuttle can reach any position in the warehouse , free from fixed path restrictions, adapting to various complex scenarios.

Efficient Handling

Highly intelligent design enables automatic handling, conveying, lane changing, and layer switching for efficient operation.

Intelligent Scheduling

Capable of interacting with equipment such as hoists and conveyor lines to achieve multi-shuttle scheduling on the same floor and intelligent scheduling of multiple devices.

Dense Storage

Suitable for dense storage of palletized goods, significantly improving space utilization and effectively saving land use costs.

Product parameters

Category | Project | Unit | Product type | |

| Normal-temperature four-way shuttle vehicle | Cold storage four-way shuttle vehicle | |||

Basic Parameters | model | - | HCS-1500C-A | HCS-1500D-A |

| kerb weight | Kg | 330 | 330 | |

rated load | Kg | 1500 | 1500 | |

| vehicle dimensions | mm | 1059×998×125 | 1059×998×125 | |

suitable pallets | mm | 1100×1100 | 1100×1100 | |

| 1200×1000 | 1200×1000 | |||

Performance Indicators | positioning method | - | - | - |

| positioning accuracy | mm | ±2 | ±2 | |

| full-load speed | m/s | 2 | 2 | |

| no-load speed | m/s | 3 | 3 | |

| maximum acceleration | m/s² | 2 | 2 | |

| commutation time | s | 2 | 2 | |

| lifting time | s | 1.5 | 1.5 | |

Battery Indicators | applicable temperature | ℃ | -10~45 | -25~45 |

| battery capacity | V/Ah | 40Ah | 40Ah | |

| full-charge range | h | ≥8 | ≥7 | |

| full-charge charging time | h | ≤1.5 | ≤2 | |

| battery type | - | lithium iron phosphate | lithium titanate | |

| Product Certification | certification type | - | CE/FCC/MIC | CE/FCC/MIC |

How Does the Four-Way Shuttle System Work?

The four-way shuttle is the core executing unit for receiving commands and transporting pallets within an automated warehouse. Its onboard control system translates tasks from the higher-level scheduling system into specific instructions, controlling the shuttle to perform actions such as moving along sub-rails or main rails, lifting or lowering pallets, and changing directions between rails. This enables the shuttle to store, retrieve, and transport pallets efficiently. When integrated with the Warehouse Control System (WCS) and scheduling system, the shuttle network supports intelligent, high-density, and efficient warehouse operations.

Please watch the video to learn more about the working principle.

What are the Applications of HEGERLS 4-way Pallet Shuttle System

The Perfect Solution for Automated Product Turnover and Warehouse Management

The 4-way automated pallet shuttle storage system is an ideal solution for businesses aiming to optimize available space and dramatically increase productivity by handling multiple pallets per hour. It enables seamless automation and high-density storage, making it especially suitable for modern, fast-paced warehousing environments.

Massive Storage Capacity

Perfect for facilities with medium to high consumption SKUs or operations that require storing a large number of pallets per SKU.

High Product Turnover

Tailored for companies dealing with high-turnover SKUs that demand exceptionally high throughput and rapid pallet handling.

Cold Storage Ready

Ideal for refrigerated and frozen warehouses, this system minimizes the required cooling volume and eliminates the need for operator presence in low-temperature environments.

Buffer Storage

Efficiently manages temporary storage of multiple pallet unit loads, such as in shipping and staging areas, ensuring smooth logistics and flow control.

Case Study

FAQ

When Should You Install an Automated Pallet Shuttle System?

An automated pallet shuttle system is an extremely effective solution for warehouses with high product turnover, where maximizing every inch of available storage space is critical. It is also ideal for companies engaged in bulk storage of medium- to high-consumption SKUs or operations handling a large number of pallets per SKU. Additionally, the system is well-suited for cold storage environments. Its compact design significantly reduces the volume of air that needs to be cooled, leading to substantial energy savings. Moreover, automation eliminates the need for operators to work in low-temperature conditions, improving both safety and efficiency.

What Types of Pallets Can the Four-Way Shuttle System Store?

The four-way shuttle system supports a wide range of pallet types thanks to its shuttles, which are available in three different sizes to accommodate the most common pallet dimensions. All three models share the same front-facing dimension, as pallets are handled from the wider side (1,200 mm). The depth varies to match the two most typical pallet depths—1,000 mm and 1,200 mm—ensuring compatibility with standard warehouse operations.

Can the Four-Way Shuttle System Store Irregular Pallets, Half Pallets, or Non-Palletized Loads?

Yes, although not directly. The Four-Way Shuttle System can accommodate irregularly sized pallets by placing them on standard pallets that are compatible with both the shuttle and the racking system. These standard pallets act as slave pallets to ensure smooth handling and storage.

For non-standard unit loads such as intermediate bulk containers (IBCs) or big bags, the loads should first be placed on pallets. Once properly palletized, they can be safely stored on the racking rails using the Four-Way Shuttle System.