Stacker Crane System

- HEGERLS

- Xinhe Industrial Park, Hebei, China

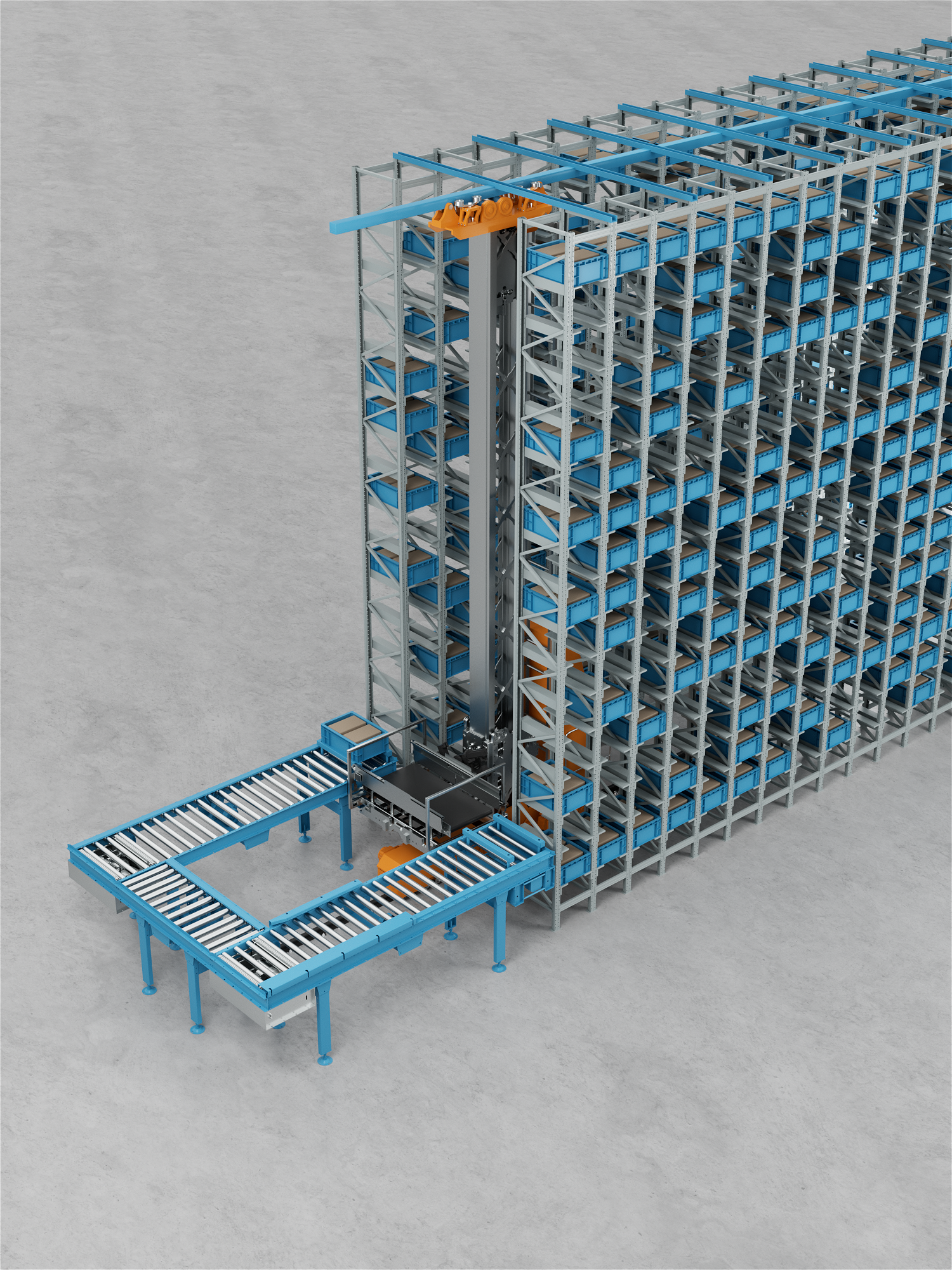

Stacker Crane: Automated, Fast, and Error-Free Storage

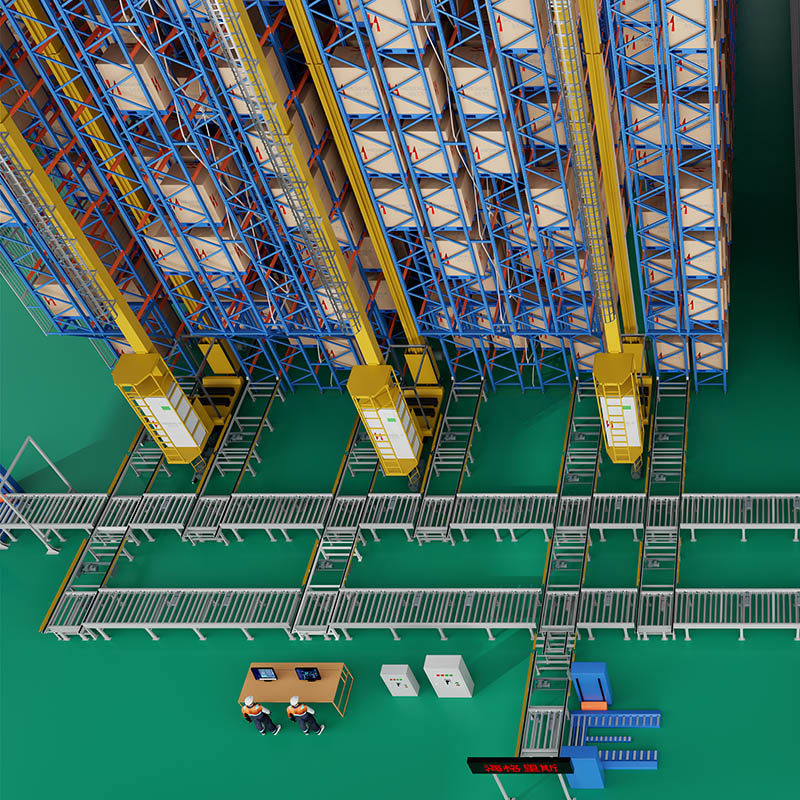

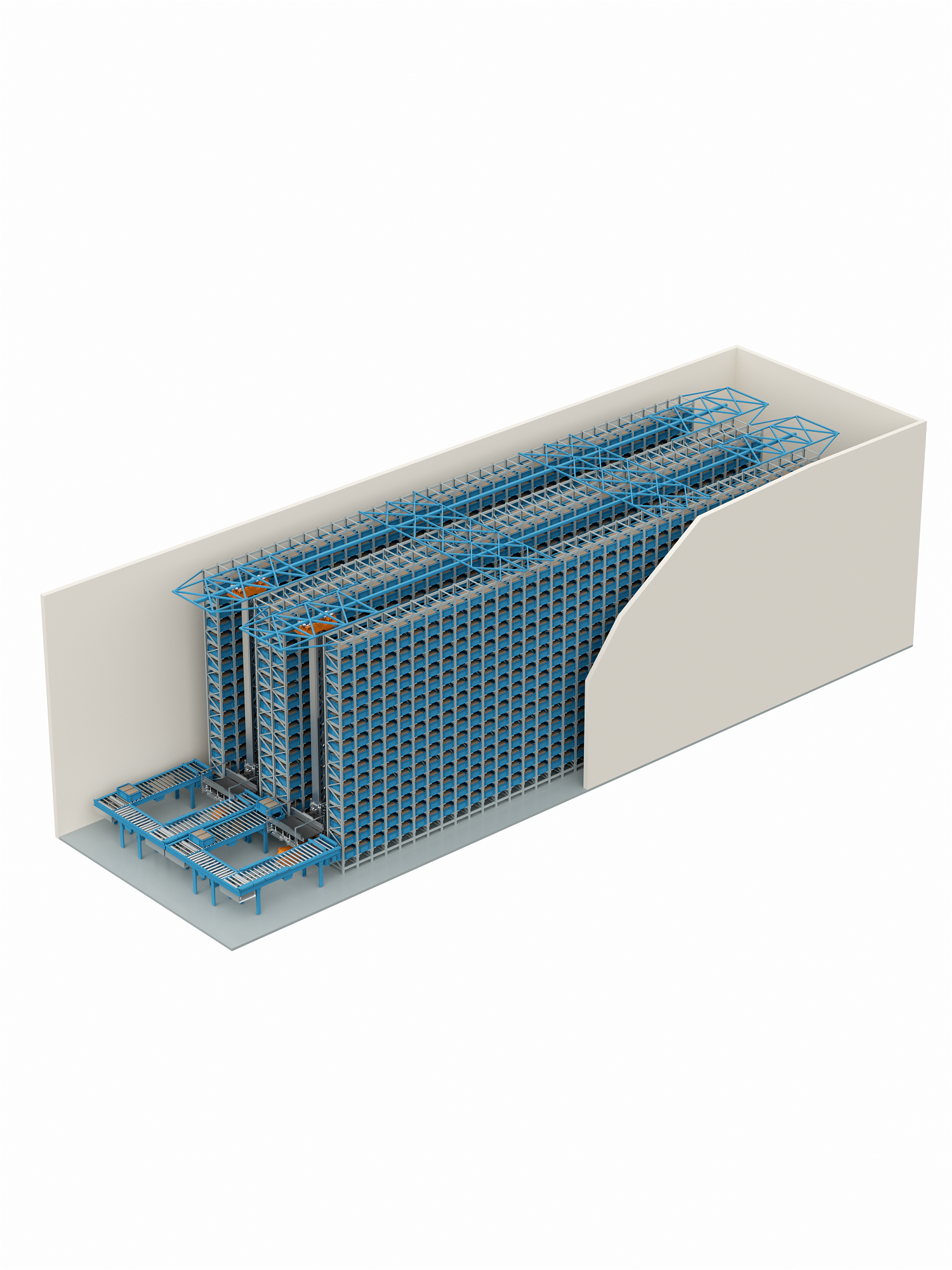

HEGERLS automated warehouse stacker crane system integrates high-rise racking, stacker cranes, conveyors, warehouse control, and management systems. By replacing manual storage and picking with automated stacker cranes, it delivers faster, safer, and more efficient operations. As workers no longer need to enter storage aisles, the work environment is greatly improved. With computer-based management, inventory handling, stocktaking, and reporting become simple and accurate, enhancing warehouse efficiency, accuracy, and reliability for modern logistics.

Types of HEGERLS Stacker Cranes

HEGERLS offers two advanced stacker crane solutions tailored to different warehouse needs:

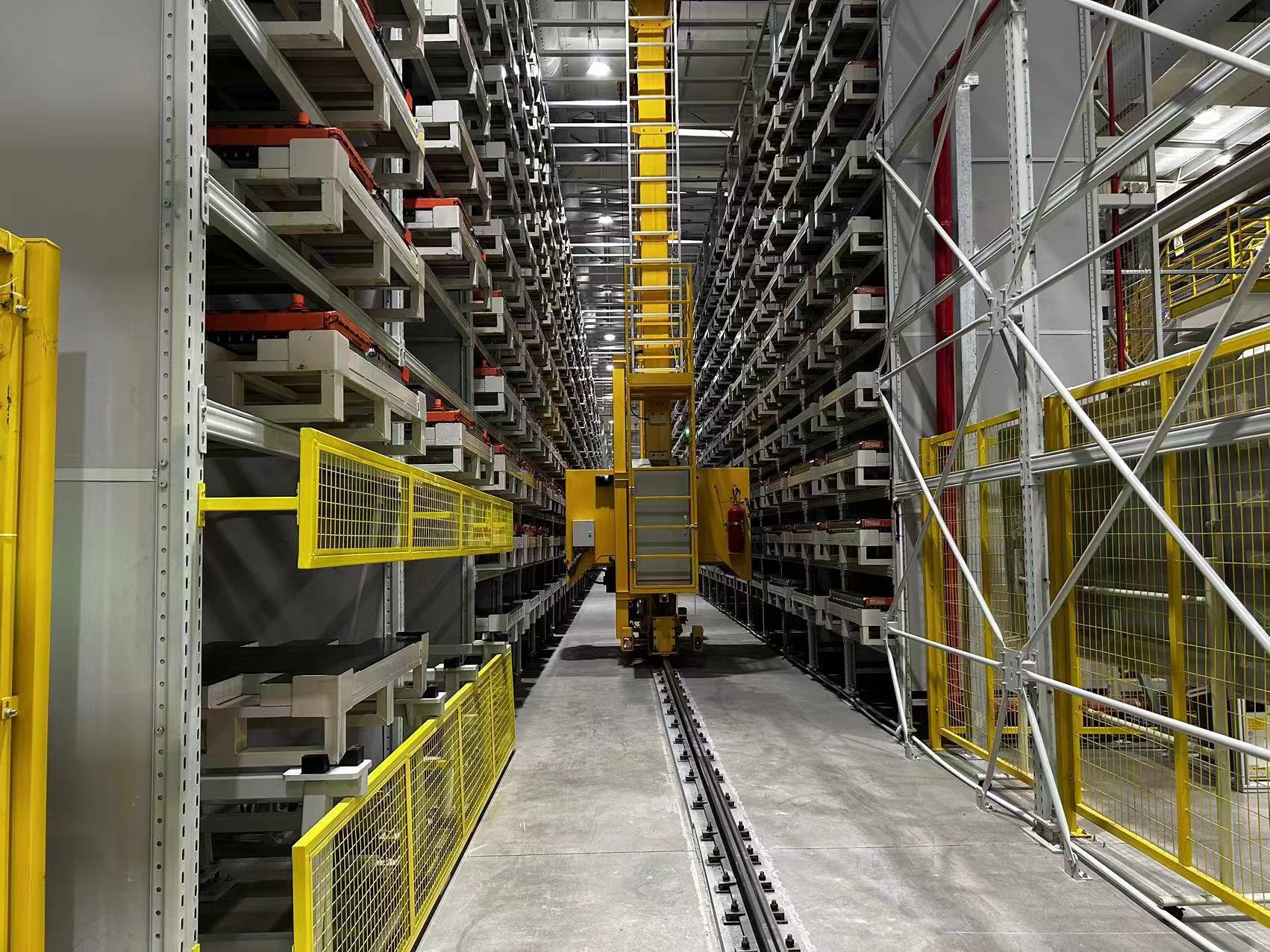

Pallet Rail Stacker Crane

The HEGERLS pallet rail stacker crane is designed for high-density pallet storage, available in single or double-column models. It supports pallet sizes from 500×500 mm to 1300×1300 mm, with loads up to 2000 kg and heights up to 40 m. Powered by frequency or servo drive, it achieves travel speeds up to 180 m/min and lift/fork speeds up to 60 m/min. With multiple fork options and flexible load positions, it ensures efficient, reliable handling. Ideal for manufacturing, distribution, and cold storage warehouses.

Pallet Rail Stacker Crane Specifications | ||

Specification | HGLS-D-DDJ-P | HGLS-S-DDJ-P |

Structure | Double Column | Single Column |

Pallet Size | 500 × 500 – 1300 × 1300 mm | |

Move Type | Straight / Turn / Crossover / Rail Transfer Car | |

Structure Height | 3 m – 40 m | 3 m – 33 m |

Lift Capacity | 200 kg – 2000 kg | |

Travel Speed | 0 – 180 m/min (Frequency / Servo Control) | |

Lift Speed | 0 – 60 m/min (Frequency / Servo Control) | |

Fork Speed | 0 – 60 m/min (Frequency / Servo Control) | |

Load Type | Single / Double / Multi-position | |

Power Supply | Sliding Contact Line / Cable | |

Fork Type | Single Fork / Double Deep Fork / Special Fork | |

Option | Picking Station / Camera / Clamp | |

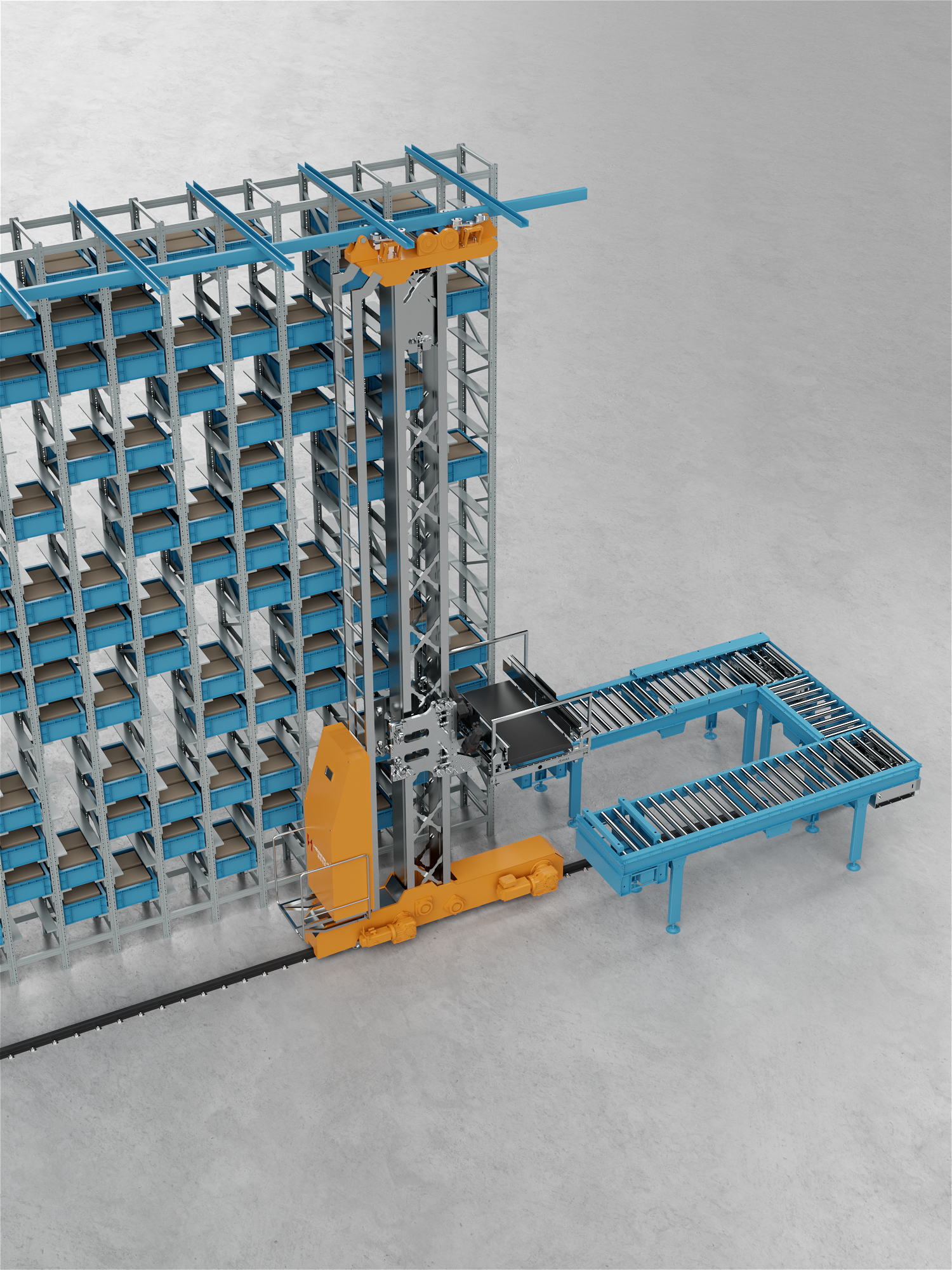

Miniload Stacker Crane

The HEGERLS miniload stacker crane is built for bins, cartons, and totes, handling sizes from 200×200 mm to 650×650 mm with loads of 5–100 kg. Its servo-driven system delivers travel speeds up to 240 m/min, ensuring fast and precise operations in compact warehouses. Fork options include single, double, clamp, and extractable designs, with flexible loading configurations. Optional cameras and clamps enhance efficiency. Perfect for e-commerce, pharmaceuticals, electronics, and spare parts storage requiring speed and accuracy.

Miniload Stacker Crane Specifications | ||

Specification | HGLS-D-DDJ-M | HGLS-S-DDJ-M |

Structure Type | Double Column | Single Column |

Pallet Size | 200 × 200 – 650 × 650 mm | |

Move Type | Straight / Turn / Crossover | |

Structure Height | 3 m – 21 m | |

Lift Capacity | 5 kg – 100 kg | |

Travel Speed | 0 – 240 m/min (Frequency / Servo Control) | |

Lift Speed | 0 – 60 m/min (Frequency / Servo Control) | |

Fork Speed | 0 – 60 m/min (Frequency / Servo Control) | |

Load Type | Single / Double / Multi-position | |

Power Supply | Sliding Contact Line / Cable | |

Fork Type | Single Fork / Double Deep Fork / Special Fork | |

Option | Camera / Material Clamp | |

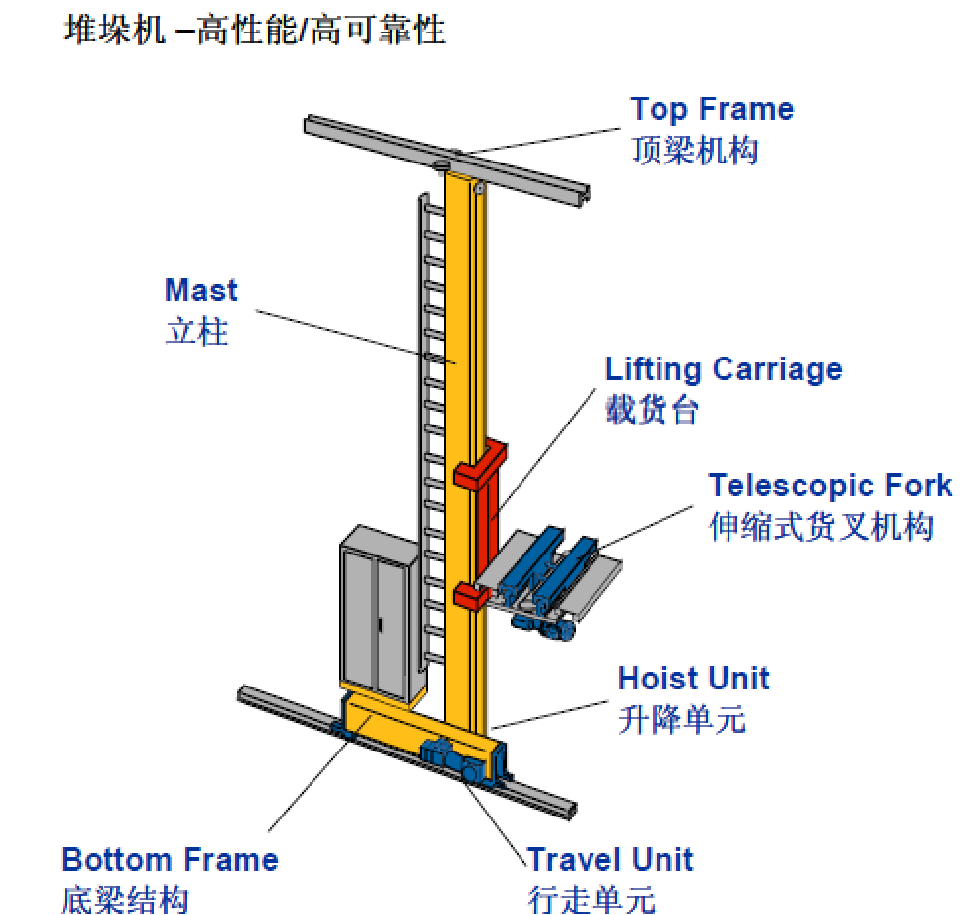

How Does a Stacker Crane Work?

A stacker crane fully automates the storage and retrieval of pallets by performing three coordinated movements: longitudinal (traveling along the aisle), vertical (lifting to various rack levels), and crosswise (fork movement to store or retrieve pallets from the rack depth).

1.Pallet Delivery to the Aisle

Conveyors located beside the automated warehouse transport the pallet to the end of the designated aisle.

2. Pallet Pick-Up

The extraction system picks up the pallet and places it onto the lifting platform of the stacker crane.

3. Aisle Travel and Positioning

Guided by the Warehouse Management System (WMS), the stacker crane travels along the aisle while simultaneously lifting the pallet to the target height.

4. Pallet Storage

The extraction system inserts the pallet into the designated rack location with precision.

5. Combined Cycle (Dual Operation)

After storing a pallet, the stacker crane immediately moves to retrieve another one—optimizing time and efficiency through a combined storage-retrieval cycle.

6. Pallet Delivery to Outbound Conveyor

Finally, the retrieved pallet is transported back to the end of the aisle and placed onto the outbound conveyor for the next stage of the logistics process.

Please watch the video to see how the stacker crane works in action.

Benefits of HEGERLS Stacker Crane

High Storage Density: Maximizes vertical space utilization in high-bay warehouses, reducing the warehouse footprint.

Fast and Precise Operation: Enables rapid and accurate pallet handling with smooth horizontal and vertical movements.

Reduced Labor Costs: Automates storage and retrieval tasks, minimizing manual intervention and operational overhead.

Reliable Performance in Harsh Environments: Engineered for stable operation in ambient, cold, or freezer storage conditions (as low as -40°C).

Deep Storage Capabilities: Stacker cranes are compatible with high-density storage systems, such as pallet flow racks and shuttle systems. They can operate with single-deep, double-deep, or multi-deep racking configurations.

Improved Safety: Minimizes risk of human error or injury through automated, rail-guided movement and system safeguards.

Integrated System Solution: Comprehensive AS/RS solutions include the design, manufacturing, installation, and commissioning of all components—racking, stacker cranes, conveyors, as well as the Warehouse Control System (WCS) and Warehouse Management System (WMS).

Customizable Solutions: Tailored to your warehouse layout, load capacity, speed requirements, and industry standards.

Comprehensive Service & After-Sales Support: HEGERLS offer complete pre-sales planning, customized design solutions, and thorough testing to ensure the perfect fit for your needs. Our team manages equipment installation, provides training, supports operational phases, and offers ongoing system maintenance and remote technical assistance for seamless performance.

Application Scenarios

Stacker crane systems are widely used in high-density, automated storage environments where efficiency and space optimization are critical. Common applications include:

Automated Warehouses: For fast, accurate pallet or bin storage and retrieval.

Cold Chain Storage: Operates efficiently in low-temperature environments for food and pharmaceuticals.

Manufacturing Facilities: Integrates with production lines for raw material storage and just-in-time supply.

Distribution Centers: Enables rapid order picking and inventory turnover.

E-commerce Fulfillment: Supports high-speed, small-item picking in miniload ASRS systems.

These systems are ideal for industries like retail, food & beverage, automotive, pharmaceuticals, and electronics, where precision, speed, and reliability are essential.

Operation log function

Stacker maintenance reminder function

Automatic cargo allocation function

Onboard touch operation function

Horizontal movement anti-shake function

Machine fault self-diagnosis function

Power-off hold function

18 types of safety protection

Case Study

Thailand Stacker Crane Solution

In this project, a fully automated vertical warehouse was implemented for Thai A&S Auto Parts to enhance storage efficiency and streamline operations. The system includes:

3 single-reach stacker cranes operating in 3 aisle lanes,

1,280 pallet storage locations,

35 units of conveyor equipment,

Integrated warehouse management software (WMS) and automated control systems for seamless coordination and real-time monitoring.

This project showcases a highly automated AS/RS solution, where stacker cranes play a central role in achieving high-density storage, accurate pallet handling, and round-the-clock operational efficiency. It stands as a benchmark for advanced warehouse automation solutions in the region.

South Africa Stacker Crane Project

This project involves a compact yet highly efficient automated warehouse solution for XF MDF in South Africa. The system is designed to optimize material handling and improve storage accuracy for medium density fiberboard products.

Key highlights of the project include:

1 single-reach stacker crane operating within 1 aisle lane,

500 pallet storage locations,

2 conveyor units for inbound and outbound handling,

Integrated automated control system and warehouse management & monitoring software for centralized operation and real-time visibility.

This project demonstrates how even a single-lane AS/RS system equipped with a stacker crane can significantly improve warehouse automation, space utilization, and operational efficiency—serving as a practical model for industrial storage in international markets.

FAQ

What is a stacker crane system?

A stacker crane system is an automated machine used in high-bay warehouses to store and retrieve goods from racking systems. It moves horizontally and vertically along rails to handle pallets or containers with precision. Stacker cranes improve storage density, speed, and efficiency in automated storage and retrieval systems (ASRS).

Which Storage Systems Are Compatible with Pallet Stacker Cranes?

Pallet stacker cranes are highly versatile and can operate seamlessly with various high-density storage systems, including:

Single-deep racking

Double-deep racking

Pallet flow racking

Automated pallet shuttle systems

These configurations allow businesses to tailor their storage solutions based on throughput requirements, space constraints, and operational complexity—maximizing both efficiency and storage capacity.

Can a Stacker Crane Only Handle Pallets?

While pallet stacker cranes are primarily designed for storing and retrieving palletized loads, stacker cranes are also available for handling smaller unit loads.

These mini-load stacker cranes are specifically designed for small load systems, capable of managing items such as bins, cartons, trays, and even tires.

This flexibility allows stacker cranes to be adapted for a wide range of industries—from heavy-duty pallet storage to high-speed order picking in e-commerce, pharmaceutical, or automotive parts warehouses.

Can a Stacker Crane Be Installed in a Traditional Warehouse?

Yes, stacker cranes—especially automated triple-aisle models—can be installed in traditional warehouses. These systems can automate pallet racks up to 14 meters high that were previously served by manual forklifts, without modifying the existing racking.

For other rack types, automation may require structural changes. We offer expert guidance to help design the best-fit automated solutions based on each facility’s conditions. Conatct us for more information.

Optimize Your Warehouse with Smart Automation?

Discover how our Stacker Crane System can transform your storage efficiency and operational speed.

Contact us today for a customized solution or to request a free quote.