Rack Supported Warehouse

- HEGERLS

- Xinhe Industrial Park, Hebei, China

Product Introduction

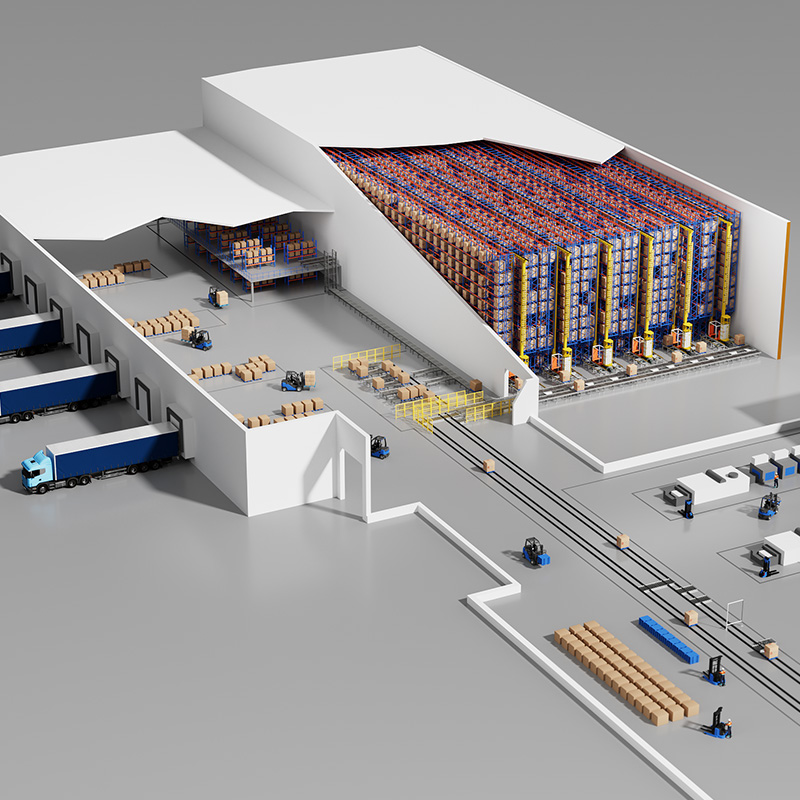

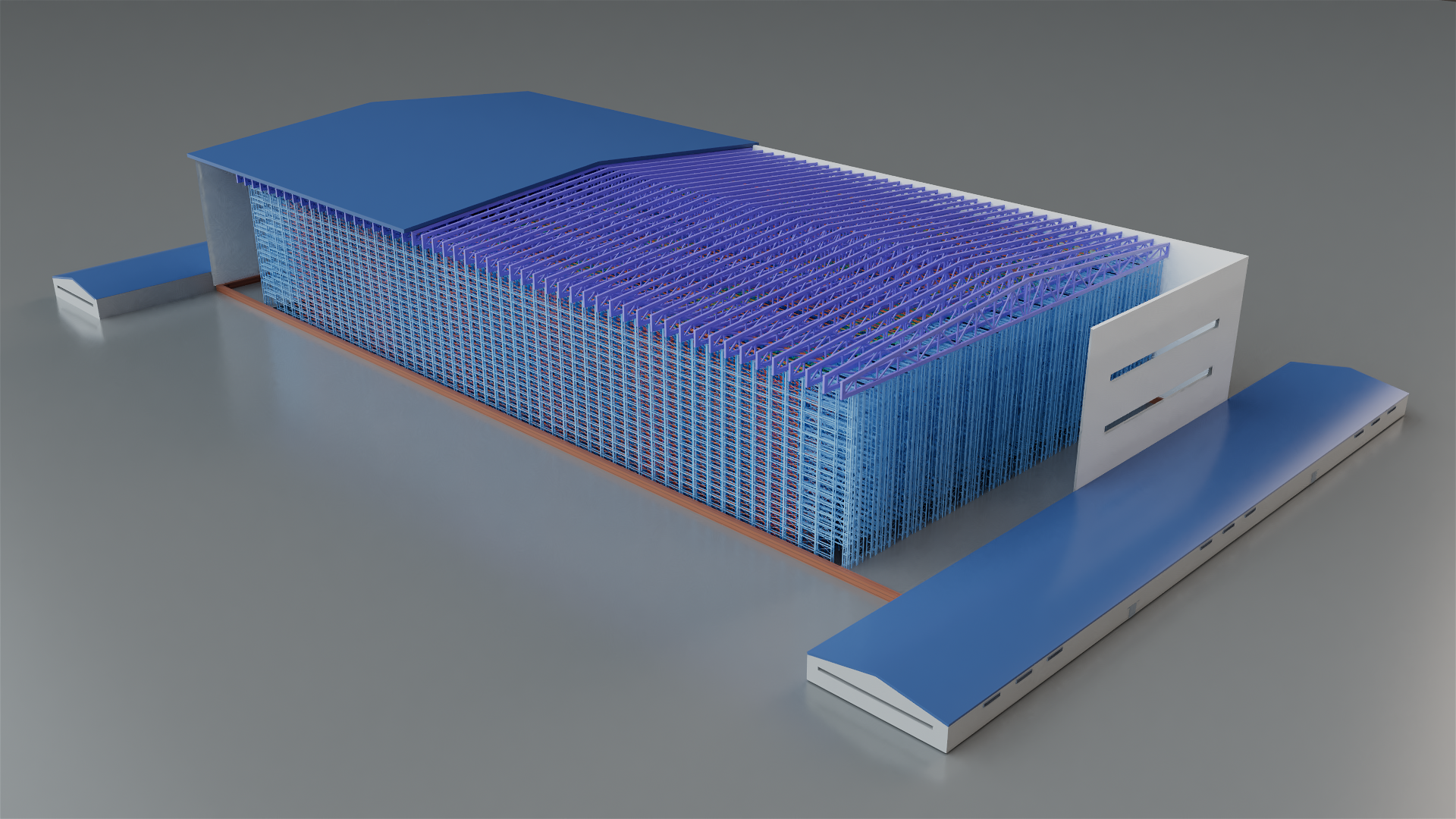

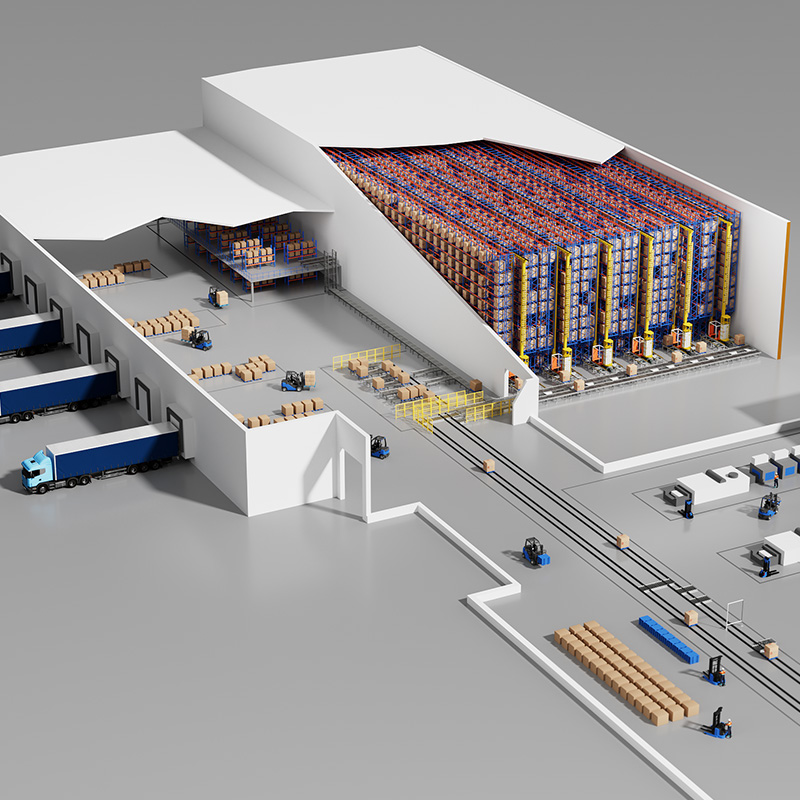

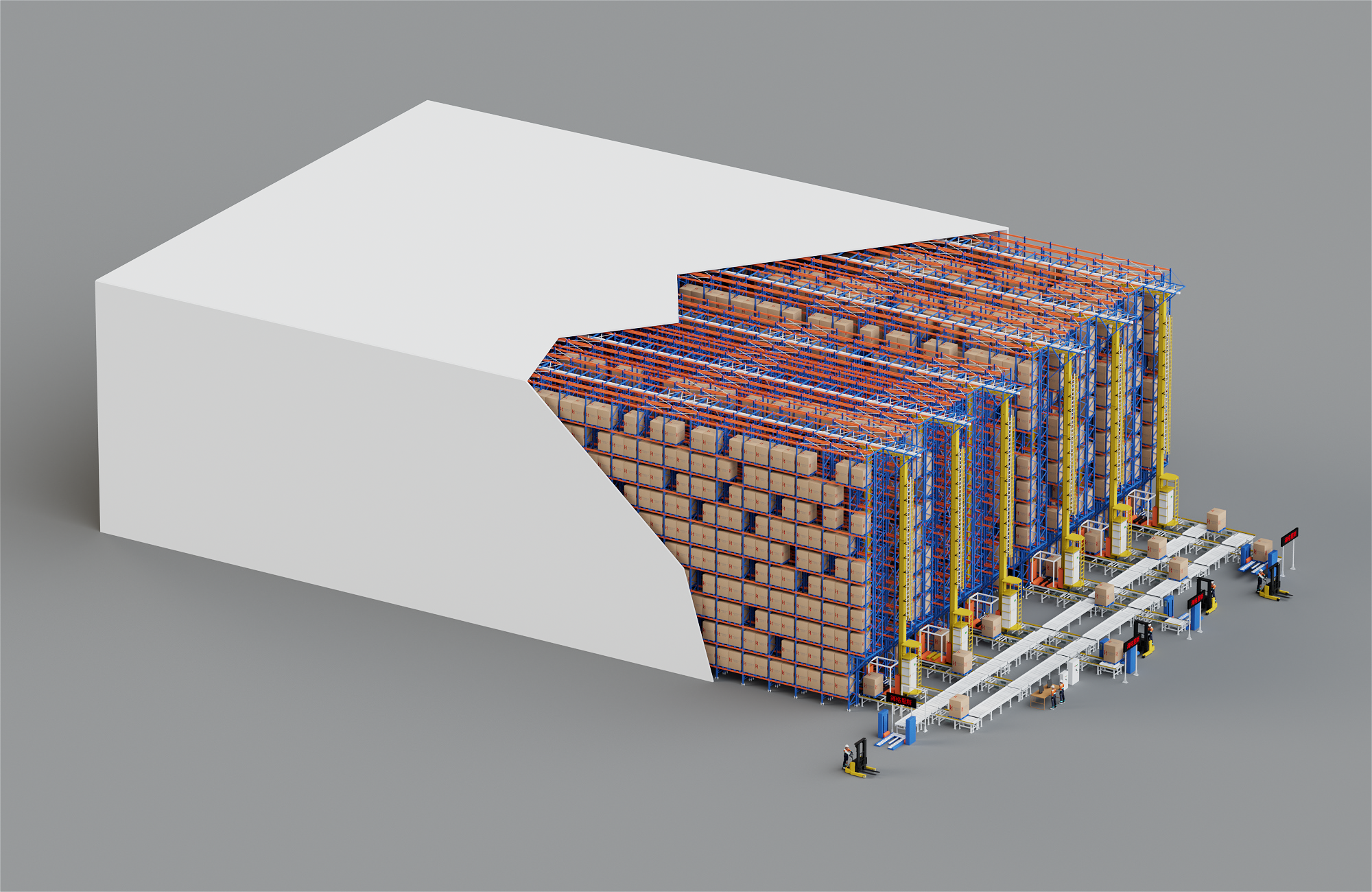

Racking supported buildings refer to the perfect integration of the warehouse and the rack, using the rack as the main building structure to support the exterior walls and the roof. In addition to external factors such as side wall panels, roof cladding, wind pressure, snow load, earthquake, and roof drainage, the rack also bears the weight of the stored goods. Therefore, compared with traditional building systems, the civil engineering work required for a shelf-supported warehouse is less, which simplifies the assembly process and reduces the comprehensive construction cost.

The self-supporting racked warehouse makes full use of more space, and the height of the warehouse building can reach 45 meters. Its versatility makes the rack-supported warehouse stand out: it can be designed with various storage solutions, ranging from traditional equipment to fully automated storage systems (AS/RS). Hegerls will accompany customers throughout the entire process, from the design and planning stage in the early project phase to the full delivery of the racked self-supported warehouse for the customer to put into use.

The Advantages Of A Rack-Supported Warehouse

Significant reduction in construction period: The installation of the goods shelves can be carried out simultaneously with the peripheral structures such as the exterior walls and the roof. This avoids the process in a traditional warehouse where the main building body needs to be completed first before installing the racks. The total construction period can be shortened by 30%.

Low construction cost: In a traditional warehouse, additional structures such as walls and roofs need to be built. However, the overall cost of the shelves in a rack-supported warehouse is 20% to 30% lower than that of the traditional warehouse solution.

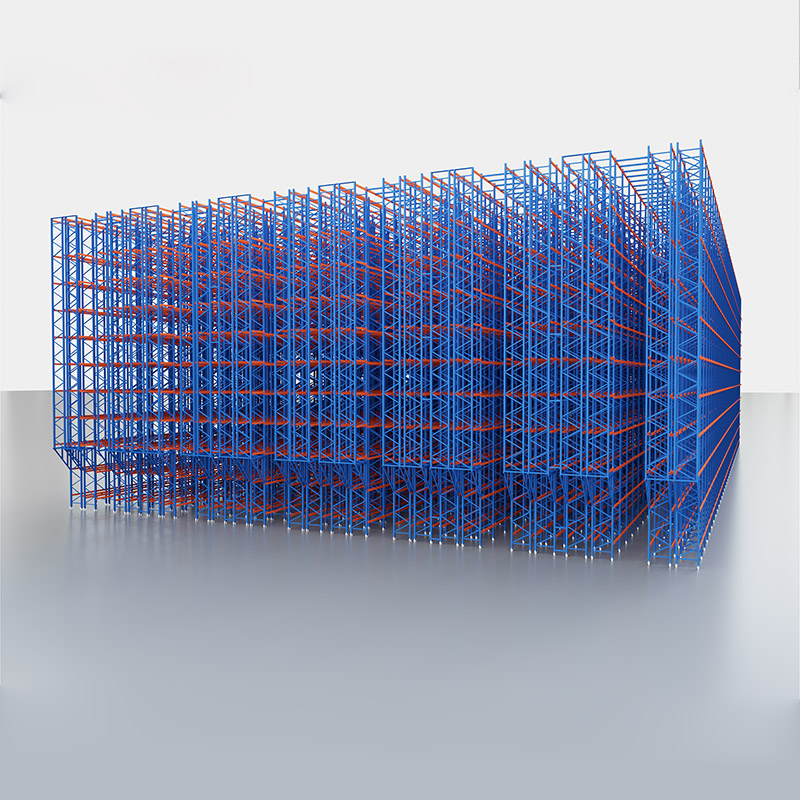

In terms of height: Clad rack warehouses have a high utilization rate of vertical space and can reach a maximum height of 45 meters. Their height is only limited by local policies and the height range of the handling equipment used.

In terms of volume: In clad rack warehouses, the goods shelves serve as the main supporting structure. There are no steel columns of traditional structures inside the warehouse, and the shelves can be closely attached to the boundaries of the storage room, resulting in a higher storage density.

Adaptation to the requirements of automation and intelligence: Its structural design can be compatible with automatic equipment (such as stacker cranes, AGVs, four-way shuttles and other automation).

Energy conservation and environmental protection: It reduces the building's energy consumption. With a compact structure, it can lower the overall energy consumption of the warehouse, which is of great significance especially for scenarios such as cold chain logistics!

Low-temperature storage: Clad rack warehouses can also be used as cold storage and freezer warehouses. The temperature inside the warehouse is uniform and stable, and electricity can be saved by up to 80%.

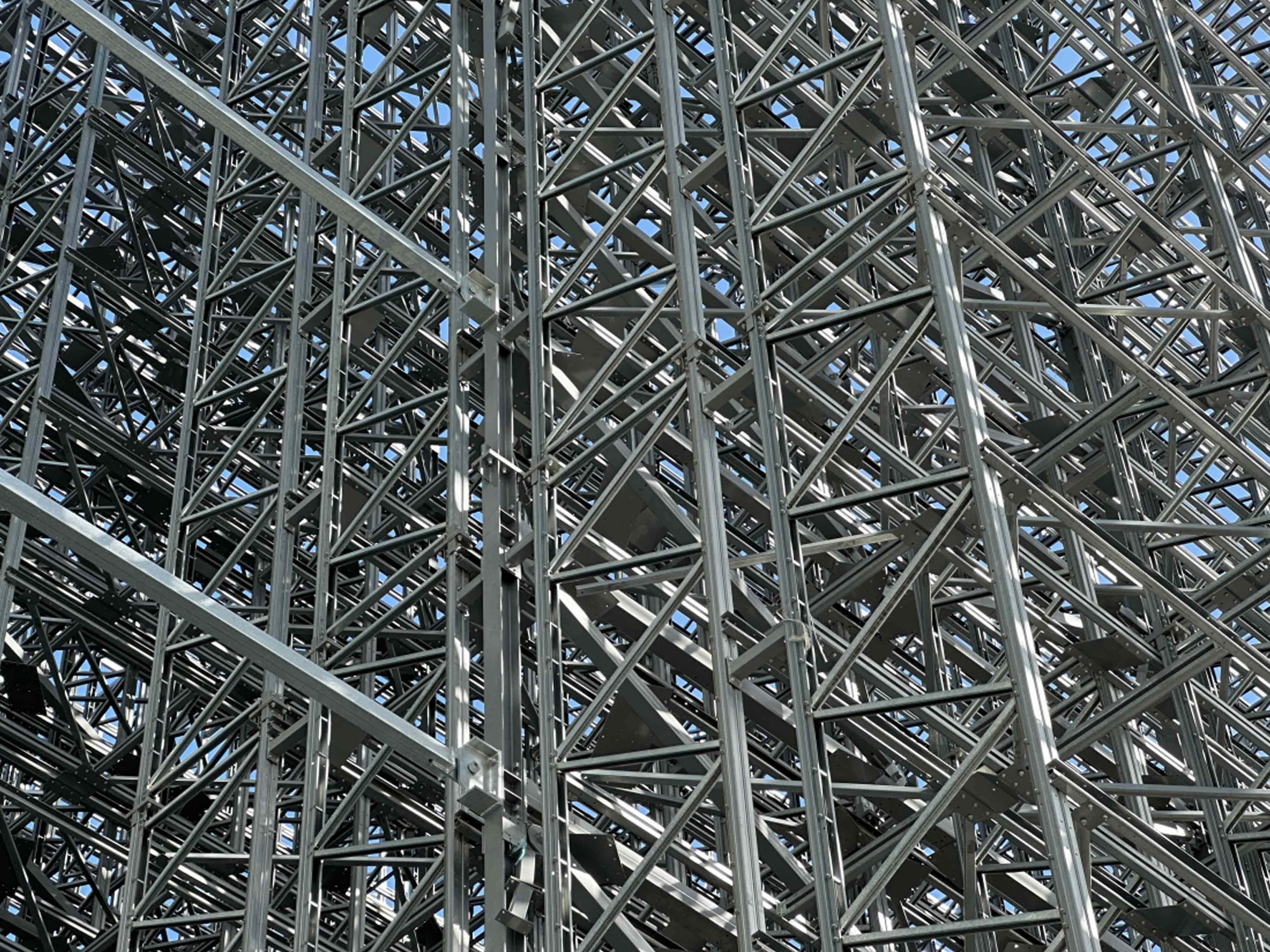

Strength and safety: A rack-supported warehouse has a particularly sturdy structure and can withstand external forces such as wind, rain, snow, and seismic movements.

Detachable: A rack-supported warehouse uses detachable fastening installation parts (such as bolts and connecting plates), which can be flexibly disassembled and assembled, and a higher proportion of components can be recycled for reuse.

The Types Of Self-Supporting Racked Warehouse

The Self-supporting Racked Warehouse can adjust its layout according to the demand and adapt to the needs of different commodities. HEGERLS can customize and design various storage solutions for each customer, ranging from traditional equipment to fully automated storage systems (AS/RS).

Automated AS/RS/Radio Shuttle Racking Supported Buildings

The Self-supporting Racked Warehouse equipped with AS/RS (such as AS/RS) makes the most of the vertical space, reaching up to 45 meters at the maximum, which improves the storage density and storage efficiency.

Self-supporting Racked Warehouse for Cold Storage

The Self-supporting Racked Warehouse can also be used for the storage of cold storage and freezers, and it is capable of storing goods at low temperatures. Both traditional and automated methods can be tailor-designed according to the actual situation of customers.

Pallet Rack Racked Self-supporting Warehouse

The Self-supporting Racked Warehouse is suitable for traditional racks where goods are accessed by forklifts. The types of shelves can be single-depth or double-depth, and can be beam-type/drive-in/through-type, etc. The height of the rack depends on the extension range of the forklift in use.

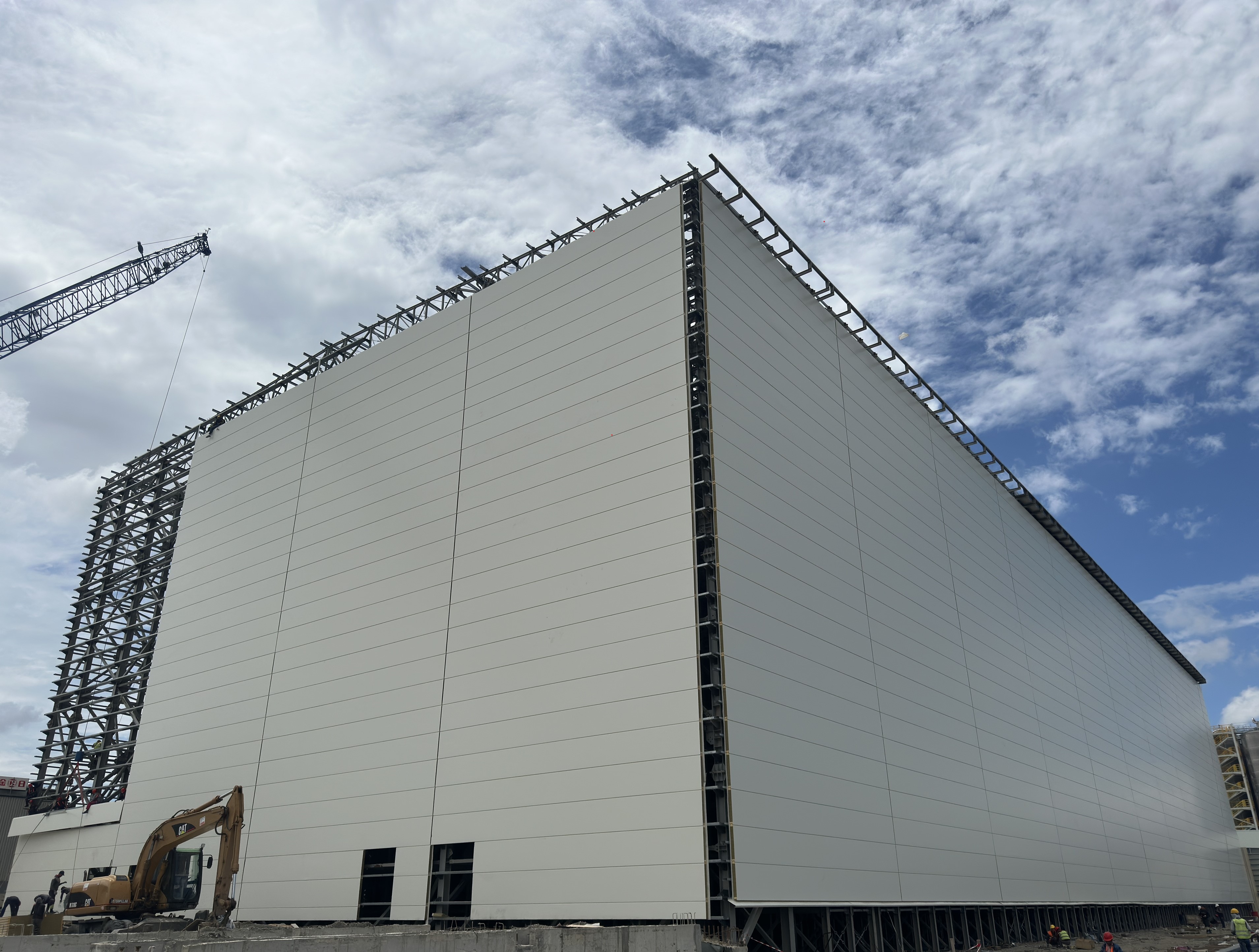

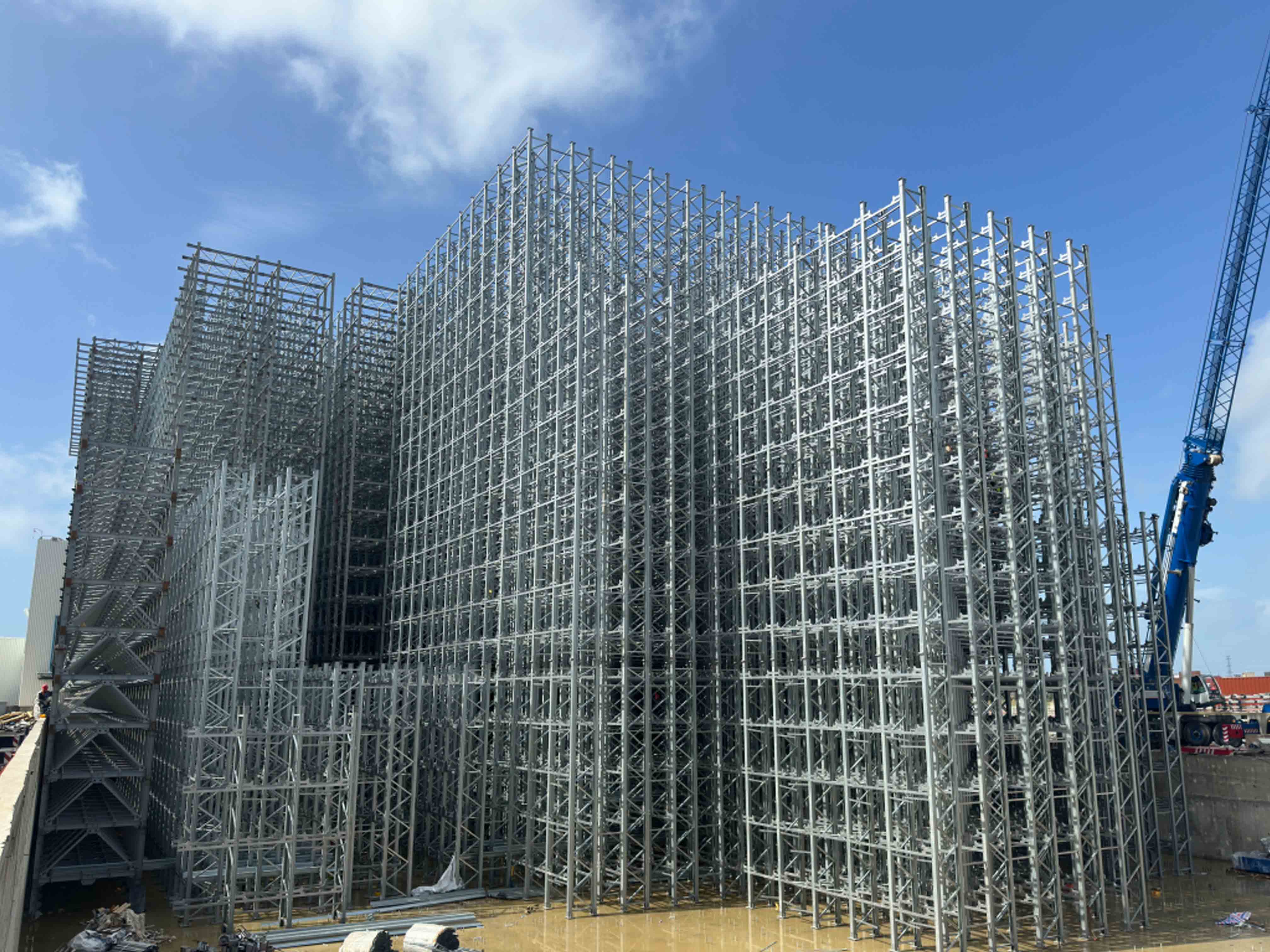

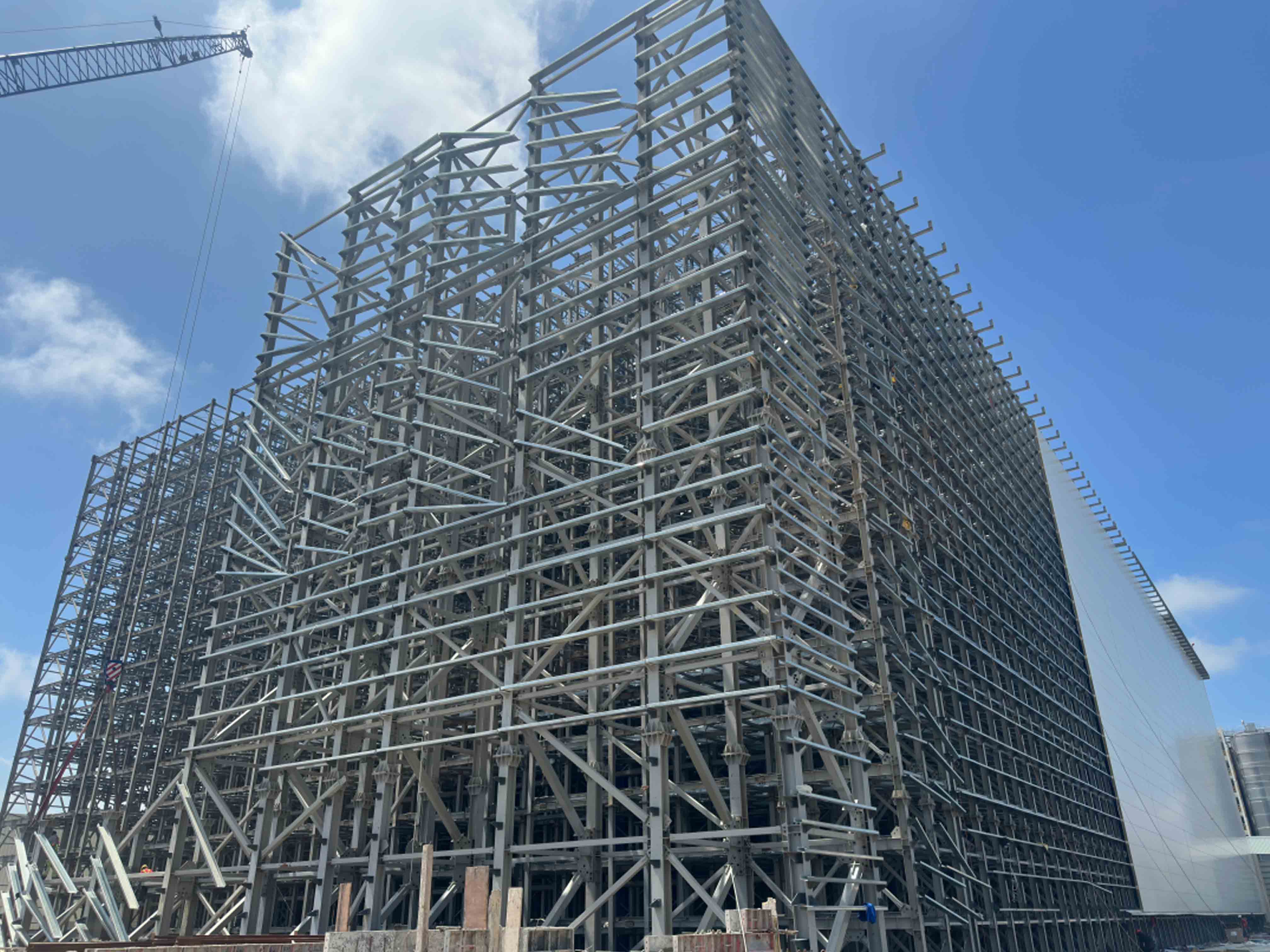

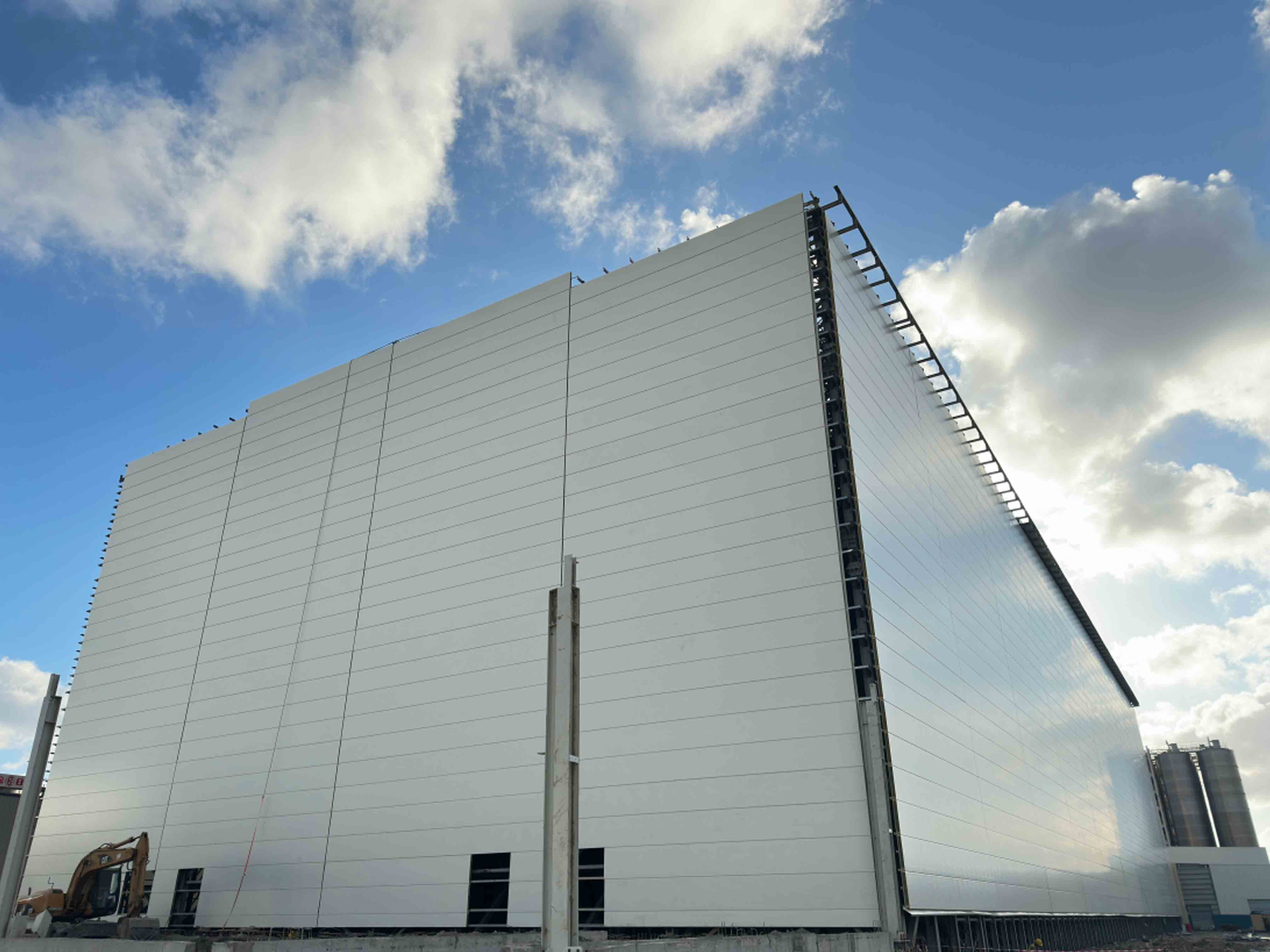

Case Pictures

The Implementation Process Of The Racked Self-Supported Warehouse

For the Racked Self-supported Warehouse, in the early stage, design and planning need to be carried out, and data calculation should be made. Then, basic construction and shelf installation should be carried out. Moreover, the shelves, equipment, fire protection facilities and wall panels should be installed simultaneously, and all these should be coordinated with each other until the project is capped. The whole process requires less construction work, takes less time, has a lower cost, and can achieve efficient and rapid acceptance and delivery.

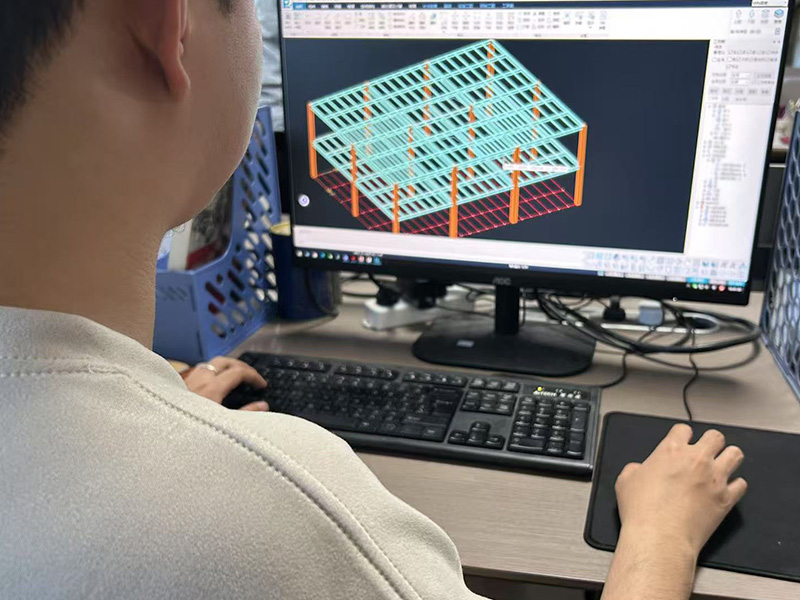

Design and Planning

Layout the racking system according to the client's requirements and conduct structural load calculations. Comprehensive calculations shall cover internal loads from stored goods and external loads such as seismic forces, wind pressure, snow, and rain to ensure structural stability.

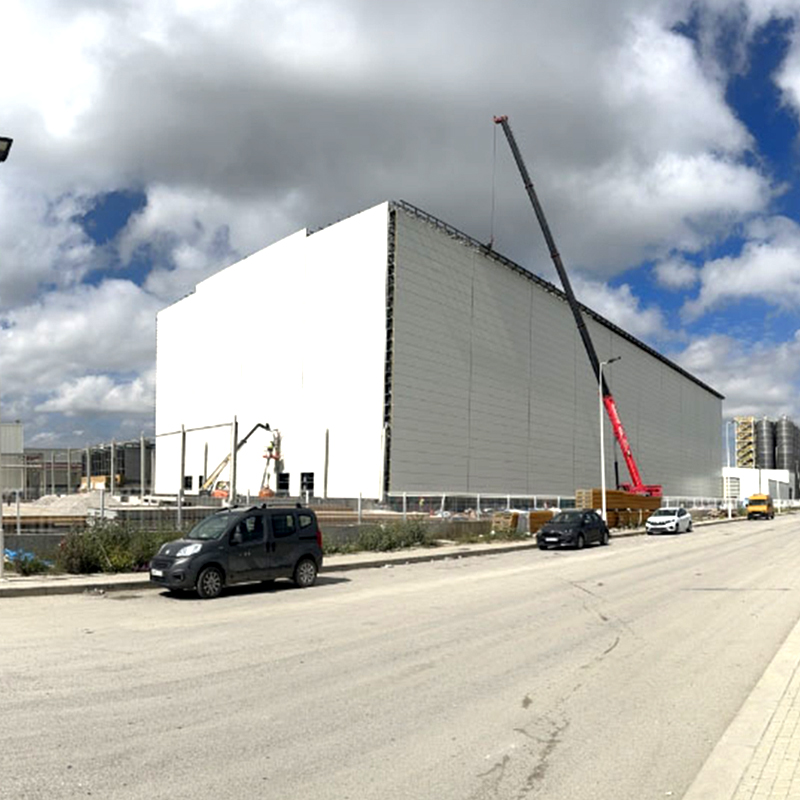

Civil Engineering Construction

The construction of the warehouse starts with the construction of the foundation and the ground.

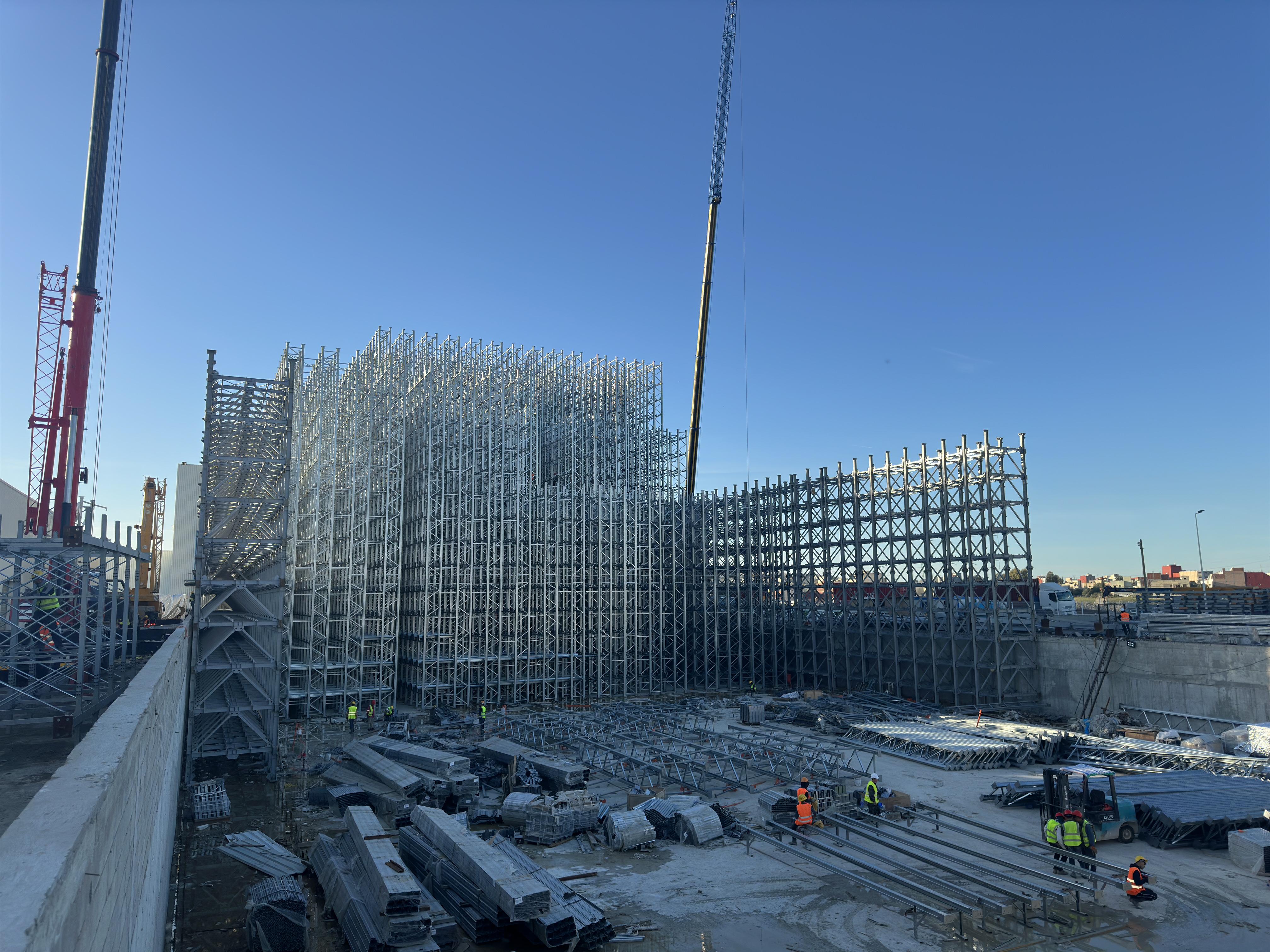

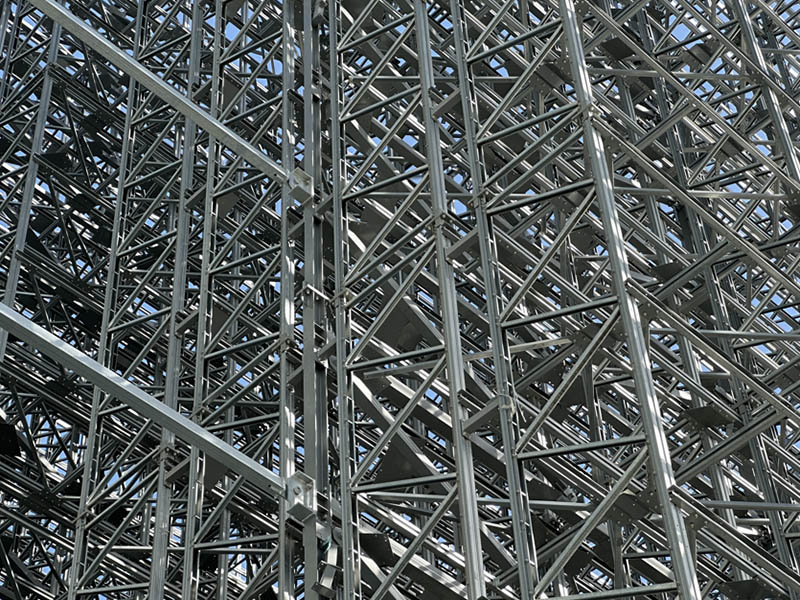

Installation of Shelf and Steel Structure

Use high-quality and high-strength steel to build the main body of the shelf. Install the steel structure and roof truss simultaneously to form the framework of the complete storage room.

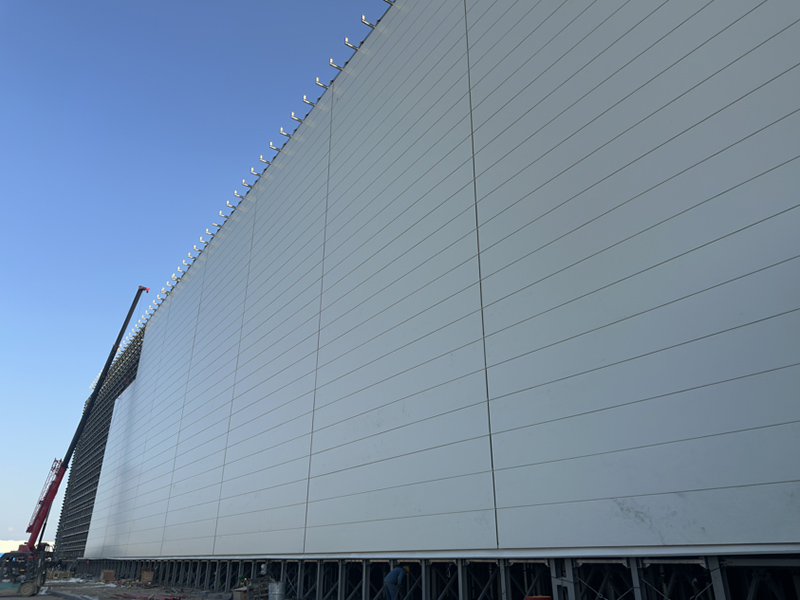

Installation of Wall Panels and Roof Panels

During the construction of the shelf, install the enclosure structure of the wall panels and roof panels according to the actual installation situation.

Automation Installation

Deploy and install equipment such as stacker cranes, roller conveyors, and radio shuttles, and configure the Warehouse Control System (WCS) and Warehouse Management System (WMS) to achieve coordinated scheduling of the equipment.

Equipment Debugging and Project Acceptance

Professional personnel will conduct on-site debugging of the equipment and provide guidance throughout the process to ensure that customers have no concerns.

Customer Feedback And Reviews

Content: The racking supported buildings constructed for us by Hegerls fully meet our requirements in terms of professionalism, craftsmanship, technology, and applicability, exceeding our expectations. I will act as their advocate.

Company: A tire company in Morocco

Position: Warehouse Project Manager

Name: Mr. Zhang

Content: Our Racked Self-supported Warehouse is truly spectacular! We are extremely grateful to Hegerls for their hard work on this project, which has led to our current achievements: the efficiency of inbound and outbound operations has increased by 200%, the number of storage locations has increased by 400%, and labor costs have been reduced by 300%.

Company: A pharmaceutical company in Thailand

Position: Purchasing Manager

Name: Kajornsak

Content: HEGERLS has extensive experience in constructing stacker-type Self-supporting Racked Warehouses for us. They have enabled us to make the most of the space and significantly increase the storage capacity. Thanks to their high-quality products and strict standards, HEGERLS has become our trusted partner.

Company: A food company in India

Position: Deputy General Manager

Name: Neeraj

Case Sharing

Case Summary: A tire company in Morocco has been continuously expanding its business scale with an annual growth rate of over 20%. In line with market development, it promptly adjusts its industrial layout. To meet the company's growing demand for storage automation and reduce the costs of constructing storage rooms and warehousing, it decided to build a rack-supported warehouse. Through on-site inspections and understanding of the company's overall operations, we provided multiple construction plans for the rack-supported warehouse based on the actual situation. Eventually, the customer chose the stacker crane rack-supported warehouse.

Solution: HEGERLS designed and constructed a shelf-supported warehouse that combines shuttle runners with stacker cranes for the company.

Explanation of Case Advantages:

The use of shuttle runner shelves in conjunction with shuttle runners enables dense storage, increasing the number of storage locations by three times compared to the original.

The use of stacker cranes for goods access has tripled the efficiency of inbound and outbound operations compared to before.

Parameters:

Number of storage locations: 35,496

Pallet size: 146511501130mm

Maximum load-bearing capacity of the tray: 1200kg

Height of the cold room: 34.9m

Case Summary: An Indian food company mainly produces and sells meat and poultry products, with 30% of its finished products exported to other countries. Previously, the company relied on traditional cold rooms for storage. However, due to the increase in production volume and the accompanying rise in operational efficiency requirements, the existing traditional frozen rooms can no longer meet the current warehousing needs. Given the limited land resources and high land costs, after our in - depth understanding and analysis of its warehousing status, and in line with its actual requirements, the company resolutely followed our advice and decided to build a shelf - supported warehouse.

Solution: HEGERLS designed and constructed a four - way shuttle shelf - supported warehouse for the company.

Explanation of Case Advantages:

It saves 20% - 30% of land occupation costs.

Increase in storage capacity: The storage capacity of the four - way shuttle shelf - supported warehouse cold room has doubled compared to the original traditional frozen room.

Labor cost savings: It shortens the working time of some personnel in the cold room, reducing labor costs by three times.

Parameters:

Storage capacity: 35,000 pallets

Tray size: 100011001800mm

Maximum tray load - bearing: 1400kg

Cold room height: 32m