[Hebei, China — October 2025] In the evolving landscape of warehouse automation, Pick-to-Light (PTL) systems are emerging as a critical layer in the order-picking process. A recent press release forecasts stronger adoption driven by e-commerce growth, automated warehouses, and retail expansion. Coupled with market forecasts showing a robust CAGR in the PTL sector, these trends highlight how smart lighting and visual guidance systems are becoming indispensable in modern logistics.

For HEGERLS, integrating Pick-to-Light into our automation stacks (shuttles, racks, WMS/WCS) offers a pathway to boost picking accuracy, speed, and user experience — particularly in hybrid warehouses blending human + machine workflows.

Market Trends & Forecasts: How Big & How Fast?

Market Size & Growth

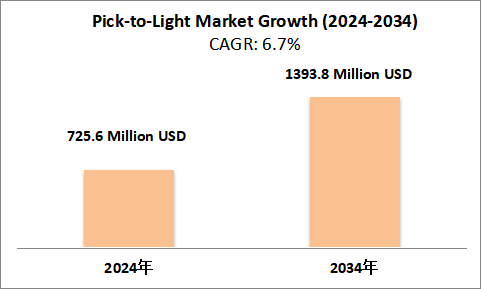

According to Future Market Insights via a press release, the Pick-to-Light market is estimated at USD 725.6 million in 2024, and is projected to grow to USD 1,393.8 million by 2034, exhibiting a CAGR of ~6.7%.

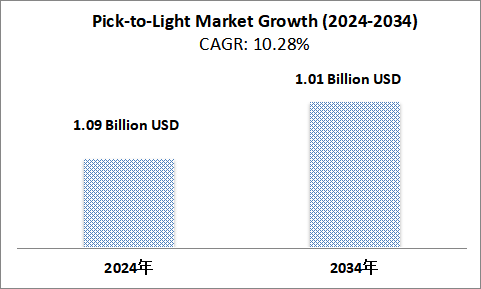

Mordor Intelligence estimates a base of USD 0.62 billion in 2025, expanding to USD 1.01 billion by 2030 at a CAGR of ~10.28%.

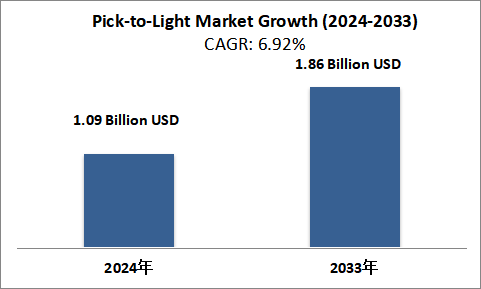

Market Growth Reports report the Pick-to-Light systems market size in 2024 as USD 1.09 billion, with projections to USD 1.86 billion by 2033, growing at ~6.92% CAGR.

Other sources present moderate variations: e.g., Technavio forecasts 7.09% CAGR in the 2024–2028 period and highlight strong adoption of wireless PTL.

While absolute numbers differ among sources, the consensus is clear: Pick-to-Light is a steadily rising segment within intralogistics, especially for e-commerce, 3PL, retail, and order fulfillment applications.

Key Drivers

E-commerce expansion & order complexity: More SKUs, more SKUs per order, faster delivery expectations — PTL systems help reduce picking errors and accelerate fulfillment.

Labor challenges & human error: High turnover, shortage of skilled pickers, and demands for accuracy in high-volume zones make visual cue systems more attractive.

Retrofit opportunities: Many warehouses already built may not be restructured — wireless PTL systems offer easier retrofitting. Technavio reports wireless PTL rising at ~12.11% CAGR.

Integration with WMS/WCS, IoT, AI: PTL systems are migrating from stand-alone tools to integrated modules of warehouse orchestration platforms.

Sector-specific adoption: Strong uptake in retail, pharmaceuticals, electronics, and 3PL sectors, where speed, accuracy, and traceability are non-negotiable.

Regional & Segment Observations

North America held ~38.23% of PTL market share in 2024; Asia-Pacific is forecast to grow strongly (~14.32% CAGR) through 2030.

Mordor Intelligence

Retrofit vs. Greenfield: In 2024, retrofit projects reportedly comprised ~65.42% of the market, suggesting many operators prefer adding to existing infrastructure rather than rebuilding.

Hardware vs. Services: Hardware still commands the major share (~71.24% in 2024) but the services segment (installation, maintenance, upgrades) is growing faster (~12.21% CAGR).

Shelf-mounted systems dominate; mobile/cart-based variants are rising in adoption.

Why Pick-to-Light Matters in Today’s Warehouses

While high-level automation (shuttles, AS/RS, robotics) often draws the spotlight, Pick-to-Light systems fulfill a crucial bridge between static storage and human tasks. Their advantages include:

Visual guidance for pickers, reducing reliance on handheld devices or voice commands

Reduced picking time by indicating precisely where to pick

Error mitigation, especially in multi-SKU or variant-heavy zones

Ease of scaling and modularity, useful for phased rollouts

Better operator experience, decreasing fatigue and training time

For operations where full automation is not (yet) feasible for all SKUs, PTL is a cost-effective middle layer.

HEGERLS’ Perspective: Integration, not Isolation

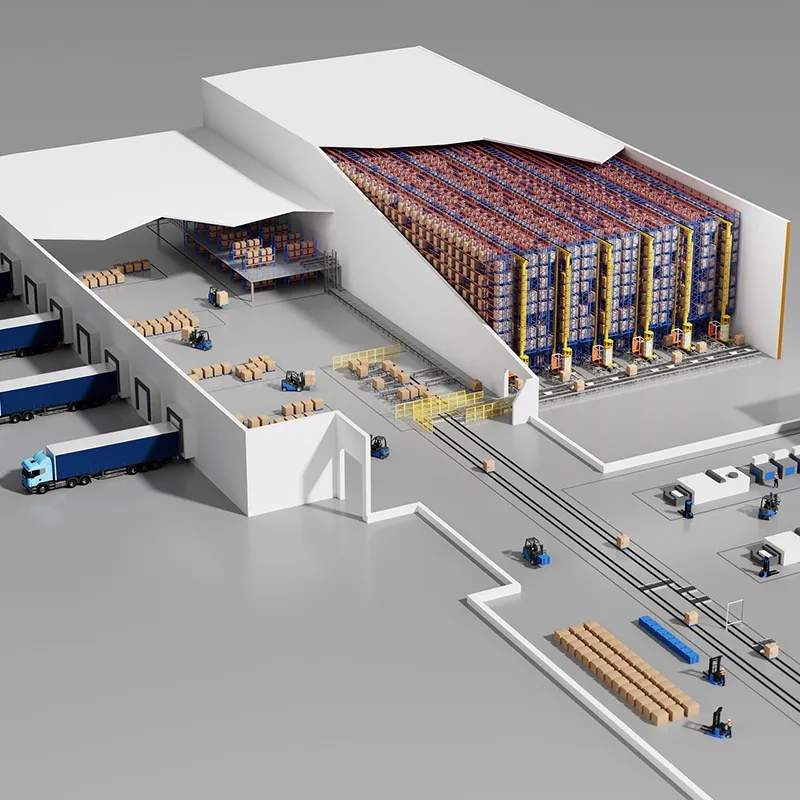

At HEGERLS, we view automation as a unified ecosystem. Every solution — whether it’s a Four-Way Shuttle System, Six-Way Shuttle System, Rack-Supported Warehouse, or Mobile Racking System — plays a coordinated role in optimizing space, speed, and precision.

Adding Pick-to-Light technology strengthens this ecosystem by addressing one of the most complex challenges in logistics: human-machine interaction in dynamic environments.

Synergy with CC-WMS and YUNTU-WCS

CC-WMS

YUNTU-WCS

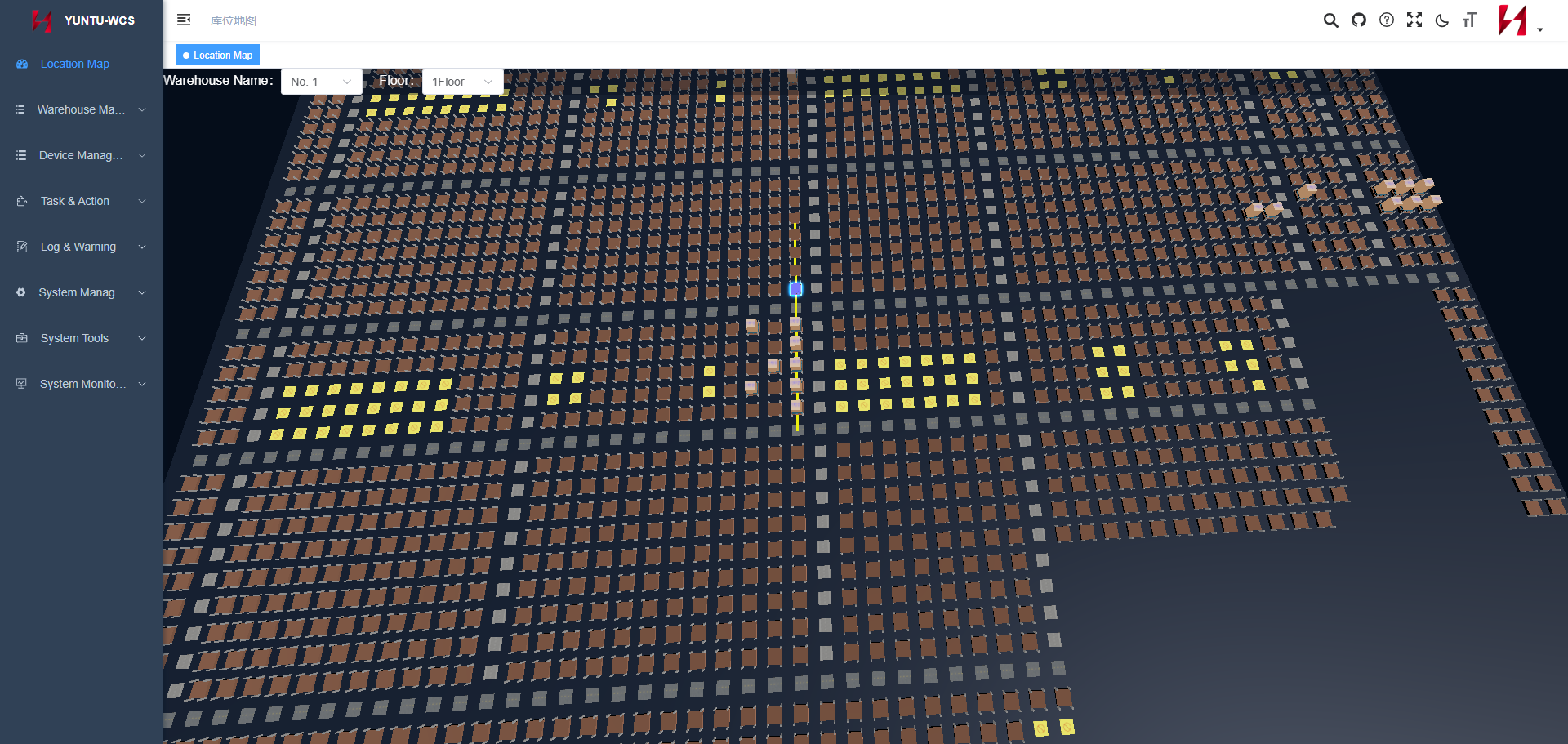

HEGERLS’ CC-WMS (Warehouse Management System) and YUNTU-WCS (Warehouse Control System) form the digital backbone of our automation solutions.

These platforms orchestrate every movement within the warehouse — from storage allocation and shuttle scheduling to picking confirmation and outbound sequencing. By integrating PTL signals directly into the WMS/WCS workflow:

The system can assign tasks, illuminate the correct picking locations, and record pick completion in real time.

Operators can achieve near-zero error rates, even in high-mix order environments.

Performance analytics provide insights into bottlenecks, workload distribution, and throughput optimization.

This tight integration turns what was once a manual process into a synchronized, data-driven operation.

Product Integration: From Storage to Picking Efficiency

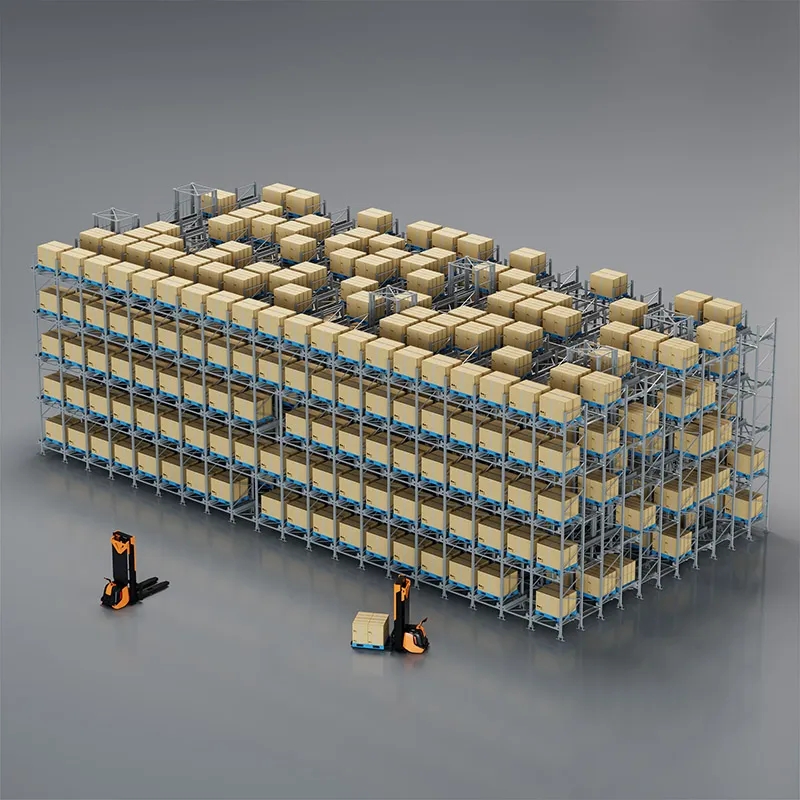

Four-Way and Six-Way Shuttle Systems

Four-Way

Six-Way Shuttle

HEGERLS advanced multi-directional shuttle systems allow for fully automated pallet handling across aisles and layers, maximizing density and flexibility.

With the integration of Pick-to-Light modules on designated picking zones, these systems can support hybrid operations — automated inbound/outbound logistics combined with manual or semi-automated picking for smaller SKUs.

In high-bay environments, HEGERLS’ rack-supported warehouses combine structural efficiency with automation intelligence.

Adding PTL technology enhances order-picking precision at ground or mezzanine levels, especially for B2C and B2B fulfillment.

For operations requiring flexibility and high selectivity, HEGERLS’ mobile racking integrates movement control with PTL visual guidance, helping operators quickly locate active pick zones.

Together, these systems illustrate HEGERLS’ philosophy: automation should enhance, not replace, human efficiency.

Innovation Under Extreme Conditions

HEGERLS has implemented PTL-compatible solutions in challenging environments — such as cold storage warehouses operating at –22°C — where conventional scanners or paper-based picking methods fail due to condensation or low visibility.

By pairing Four-Way Shuttles with Pick-to-Light indicators and CC-WMS task control, HEGERLS ensures uninterrupted operations even in frozen or high-humidity zones.

This capability positions HEGERLS as a preferred partner for cold chain logistics, food & beverage, and pharmaceutical storage sectors.

Industry Insight: From Cost Barriers to Value Creation

A recent CFO Dive report identified cost as the top barrier to warehouse robot adoption. Yet, from HEGERLS’s perspective, the key is cost efficiency through modular scalability.

Pick-to-Light systems offer a unique advantage:

They can be retrofitted into existing racking structures without full reconstruction.

They complement — rather than compete with — robotic systems.

They provide measurable ROI through faster picking speed and reduced errors, often achieving payback within 12–18 months.

HEGERLS believes the most sustainable automation strategy lies in hybrid modularization — allowing customers to scale gradually, integrating PTL, WMS, and shuttle technology as their operations grow.

Looking Forward: Toward Unified Smart Warehouses

The next decade of warehouse automation will be defined by connectivity, visibility, and adaptability.

By 2030, HEGERLS envisions fully digitalized warehouses where CC-WMS, YUNTU-WCS, AI analytics, and Pick-to-Light systems operate as one synchronized platform.

Our innovation roadmap includes:

AI-driven PTL analytics — predictive workload balancing and dynamic light assignment.

Wireless PTL modules for rapid installation and low maintenance.

Energy-saving designs, including intelligent dimming in low-activity zones.

Multi-modal interaction combining light cues with AR and voice assistance.

Through these advancements, HEGERLS aims to make warehouse automation smarter, safer, and more human-centered.

HEGERLS Commitment: From Equipment to Ecosystem

HEGERLS CoFounded on decades of manufacturing excellence, HEGERLS continues to evolve into a global smart warehousing solution provider — delivering:mmitment: From Equipment to Ecosystem

Four-Way and Six-Way Shuttle Systems

Rack-Supported Warehouses

Mobile Racking Systems

CC-WMS and YUNTU-WCS Software Suites

Pick-to-Light and Smart Picking Solutions

Each system is designed to integrate seamlessly into a cohesive digital warehouse network, empowering clients worldwide to achieve higher efficiency, reduced costs, and greater operational insight.

HEGERLS invites global partners, logistics operators, and warehouse integrators to xplore the next generation of smart intralogistics.

Discover how automated warehouse technologies can transform your warehouse into a fully connected, intelligent ecosystem.

Contact HEGERLS today to schedule a live demo or customized consultation for your automation project.