Project Overview

Client: Dingzhou Military Grain Supply Co., Ltd.

Industry: Food Supply & Emergency Reserves

Location: Dingzhou, Hebei, China

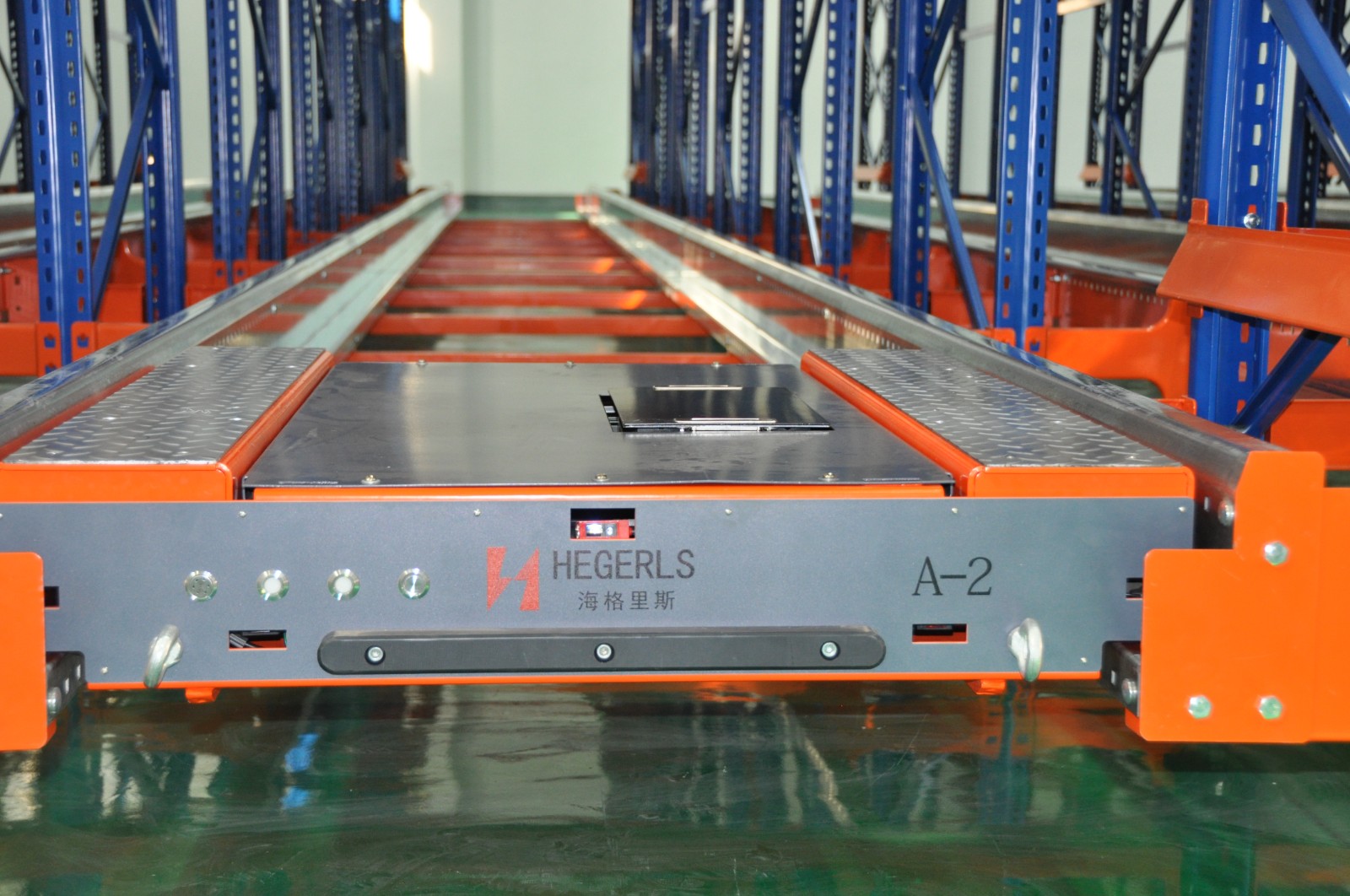

Applied Solution: HEGERLS Shuttle Racking System

Client Challenge:

As a grain reserve warehouse serving local military units, the client required highly efficient inbound and outbound operations with flexible space allocation and rapid emergency response. Traditional racking systems could not meet these strict space and automation requirements.

HEGERLS Solution:

We implemented a shuttle racking system designed to:

Maximize storage space in limited area

Achieve high-efficiency pallet handling

Support both FIFO and LIFO operations

Minimize manual labor and waiting time

Enable easy system scalability by adding more shuttles as needed

Project Highlights:

Compared to traditional beam, drive-in, or flow racking, the shuttle system occupies less ground area for the same pallet quantity and offers higher automation capability. It is the only racking type in this scenario that can flexibly switch between FIFO and LIFO, a key advantage for emergency response logistics.

Improved outbound efficiency for emergency dispatch

>80% space utilization

Reduced labor costs and operational delays

High automation within a controlled budget

Project Images: